Features & Benefits

5 in 1 concept reduces costs

The installation of a valve with 5 functions reduces the investment and the installation time.

Saves energy and money

Balanced and pressure independent circuits protects systems against over flows and too high energy consumption.

Zone control

Time controlled circuits can save up to 20% energy.

Noise protection

Differential pressure control protects control valves from too high differential pressure.

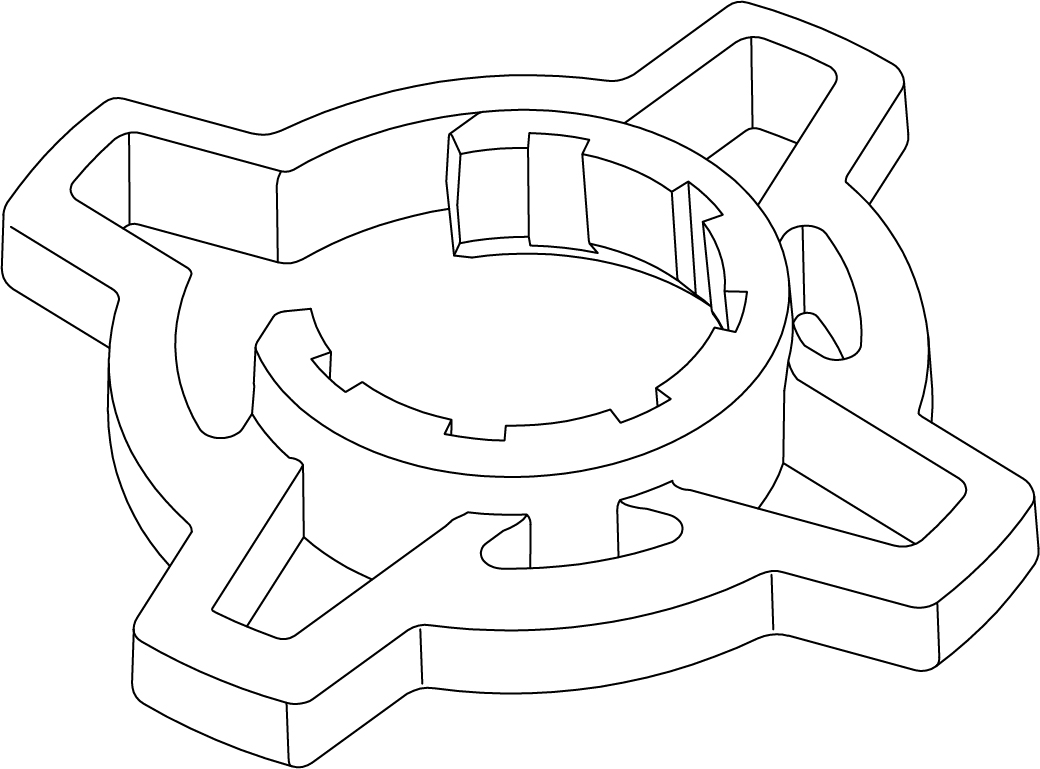

Technical Information

Application:

Heating and cooling systems.

Functions:

Pre-setting (max. flow)

Differential pressure control

Control

Measuring (ΔH, T, q)

Isolation (for use during system maintenance – see "Leakage rate")

Dimensions:

DN 10-25

Pressure class:

PN 16

Differential pressure (ΔH):

Max. differential pressure (ΔHmax):

400 kPa = 4 bar

Min. differential pressure (ΔHmin):

DN 10: 20 kPa = 0,20 bar

DN 15: 18 kPa = 0,18 bar

DN 20: 21 kPa = 0,21 bar

DN 25: 25 kPa = 0,25 bar

(Valid for the most demanding settings. Other settings will require a lower ΔH. Check with graphs under "Sizing" or software HySelect.)

ΔHmax = The maximum allowed pressure drop over the circuit, to fulfill all stated performances.

ΔHmin = The minimum needed pressure drop over the circuit, for proper differential pressure control.

Setting range:

Indication of recommended setting range. For more detailed information see "Sizing".

(ΔpL 10 kPa)

DN 10: 16-71 l/h

DN 15: 60-300 l/h

DN 20: 160-840 l/h

DN 25: 280-1500 l/h

Temperature:

Max. working temperature: 120°C

Min. working temperature: -20°C

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Lift:

4 mm

Leakage rate:

Leakage flow ≤ 0,01% of max. recommended flow (setting 10) in correct flow direction.

(Class IV according to EN 60534-4).

Characteristics:

Linear, best suited for on/off control.

Material:

Valve body: AMETAL®

Valve insert: AMETAL®

Valve plug: Brass CW724R (CuZn21Si3P)

Spindle: Stainless steel

Spindle seal: EPDM O-ring

Δp insert: AMETAL®, PPS (polyphenylsulphide)

Membrane: EPDM and HNBR

Springs: Stainless steel

O-rings: EPDM

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Marking:

TA, IMI, PN 16, DN and flow direction arrow.

Grey handwheel: TA-COMPACT-DP and DN.

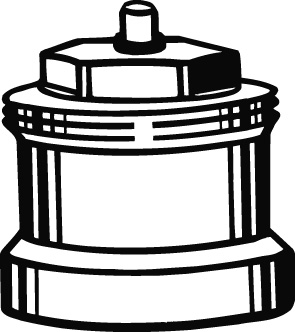

Connection:

External threads according to ISO 228.

Connection to actuator:

M30x1.5

Actuators:

See separate technical documentation on EMO T.

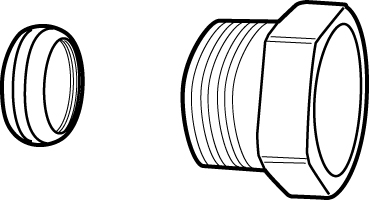

Articles

Threads according to ISO 228.

Male thread

Threads according to ISO 228.

1 m capillary pipe included.

DN | d | L | H1 | H2 | W | Kg | EAN | Article No |

10 | G1/2 | 74 | 55 | 55 | 54 | 0,57 | 7318794040205 | 52 164-210 |

15 | G3/4 | 74 | 55 | 55 | 54 | 0,60 | 7318794025608 | 52 164-215 |

20 | G1 | 85 | 64 | 55 | 64 | 0,75 | 7318794025707 | 52 164-220 |

25 | G1 1/4 | 93 | 64 | 61 | 64 | 0,90 | 7318794025806 | 52 164-225 |

*) Connection to actuator.

→ = Flow direction

Swivelling nut.

Soldering connection

Swivelling nut.

Brass/gunmetal CC491K (EN 1982)

Valve DN | D | Pipe Ø | L* | EAN | Article No |

10 | G1/2 | 10 | 10 | 7318792749100 | 52 009-510 |

10 | G1/2 | 12 | 11 | 7318792749209 | 52 009-512 |

15 | G3/4 | 15 | 13 | 7318792749308 | 52 009-515 |

15 | G3/4 | 16 | 13 | 7318792749407 | 52 009-516 |

20 | G1 | 18 | 15 | 7318792749506 | 52 009-518 |

20 | G1 | 22 | 18 | 7318792749605 | 52 009-522 |

25 | G1 1/4 | 28 | 21 | 7318792749704 | 52 009-528 |

*) Fitting length (from the gasket surface to the end of the connection).

For connection with press coupling. Swivelling nut.

Connection with smooth end

For connection with press coupling.

Swivelling nut.

Brass/AMETAL®

Valve DN | D | Pipe Ø | L* | EAN | Article No |

10 | G1/2 | 12 | 35 | 7318793810502 | 52 009-312 |

15 | G3/4 | 15 | 39 | 7318793810601 | 52 009-315 |

20 | G1 | 18 | 44 | 7318793810700 | 52 009-318 |

20 | G1 | 22 | 48 | 7318793810809 | 52 009-322 |

25 | G1 1/4 | 28 | 53 | 7318793810908 | 52 009-328 |

*) Fitting length (from the gasket surface to the end of the connection).

Swivelling nut.

Welding connection

Swivelling nut.

Brass/Steel 1.0045 (EN 10025-2)

Valve DN | D | Pipe DN | L* | EAN | Article No |

10 | G1/2 | 10 | 30 | 7318792748400 | 52 009-010 |

15 | G3/4 | 15 | 36 | 7318792748509 | 52 009-015 |

20 | G1 | 20 | 40 | 7318792748608 | 52 009-020 |

25 | G1 1/4 | 25 | 40 | 7318792748707 | 52 009-025 |

*) Fitting length (from the gasket surface to the end of the connection).

Threads according to ISO 7-1. Swivelling nut.

With External thread

Threads according to ISO 7-1.

Swivelling nut.

Brass

Valve DN | D | D1 | L* | EAN | Article No |

10 | - | - | - | - | - |

15 | G3/4 | R1/2 | 29 | 4024052516612 | 0601-02.350 |

20 | G1 | R3/4 | 32,5 | 4024052516810 | 0601-03.350 |

25 | G1 1/4 | R1 | 35 | 4024052517015 | 0601-04.350 |

*) Fitting length (from the gasket surface to the end of the connection).

Compression connection

Support bushes shall be used, for more information see catalogue leaflet FPL.

Should not be used with PEX pipes.

Brass/AMETAL®

Chrome plated

Valve DN | D | Pipe Ø | L** | EAN | Article No |

10 | G1/2 | 8 | 16 | 7318793620002 | 53 319-208 |

10 | G1/2 | 10 | 17 | 7318793620101 | 53 319-210 |

10 | G1/2 | 12 | 17 | 7318793620200 | 53 319-212 |

10 | G1/2 | 15 | 20 | 7318793620309 | 53 319-215 |

10 | G1/2 | 16 | 25 | 7318793620408 | 53 319-216 |

15 | G3/4 | 15 | 27 | 7318793705006 | 53 319-615 |

15 | G3/4 | 18 | 27 | 7318793705105 | 53 319-618 |

15 | G3/4 | 22 | 27 | 7318793705204 | 53 319-622 |

**) Over all length L refers to unassembled coupling.

Threads according to ISO 228.

With internal thread

Threads according to ISO 228.

Thread length according to ISO 7-1.

Swivelling nut.

Brass/AMETAL®

Valve DN | D | D1 | L* | EAN | Article No |

10 | G1/2 | G3/8 | 21 | 7318794016804 | 52 163-010 |

15 | G3/4 | G1/2 | 21 | 7318794016903 | 52 163-015 |

20 | G1 | G3/4 | 23 | 7318794017009 | 52 163-020 |

25 | G1 1/4 | G1 | 23 | 7318794017108 | 52 163-025 |

*) Fitting length (from the gasket surface to the end of the connection).

For better grip when presetting.For TA-COMPACT-P/-DP and TA-Modulator (DN 10-32).

Grip for setting wheel, optional

For better grip when presetting.

For TA-COMPACT-P/-DP and TA-Modulator (DN 10-32).

Colour | EAN | Article No |

Orange | 7318794040502 | 52 164-950 |

Complete with connections for 6 mm pipe

Extension kit for capillary pipe

Complete with connections for 6 mm pipe

EAN | Article No |

7318793781505 | 52 265-212 |

For TA-COMPACT-P/-DP, TA-Modulator (DN 10-20), TBV-C/-CM.

Protection cap

For TA-COMPACT-P/-DP, TA-Modulator (DN 10-20), TBV-C/-CM.

Colour | EAN | Article No |

Red | 7318793961105 | 52 143-100 |

Set containing plastic cover and locking ring for valves with connection M30x1.5 to thermostatic head/actuator. Prevents manipulation of setting.

Tamper proof cover

Set containing plastic cover and locking ring for valves with connection M30x1.5 to thermostatic head/actuator.

Prevents manipulation of setting.

EAN | Article No |

7318794030206 | 52 164-100 |

For heating/comfort cooling.Material: EPP.Fire class: E (EN 13501-1), B2 (DIN 4102).

Insulation

For heating/comfort cooling.

Material: EPP.

Fire class: E (EN 13501-1), B2 (DIN 4102).

The insulation must be manually adjusted for the capillary pipe.

Valve DN | L | H1 | H2 | D | EAN | Article No |

10-15 | 100 | 61 | 71 | 84 | 7318794027404 | 52 164-901 |

20 | 118 | 67 | 79 | 90 | 7318794027503 | 52 164-902 |

25 | 127 | 71 | 84 | 104 | 7318794027602 | 52 164-903 |

For capillary pipe with G1/16 connection.

Transition nipple

For capillary pipe with G1/16 connection.

For connection to TA valves with drain.

d | EAN | Article No |

G1/2 | 7318793660206 | 52 179-981 |

G3/4 | 7318793660305 | 52 179-986 |

Capillary pipe

1 pc included in TA-COMPACT-DP.

L | EAN | Article No |

1 m | 7318793661500 | 52 265-301 |

For connection of capillary pipe while permitting simultaneous use of our balancing instrument.

Measuring point, two-way

For connection of capillary pipe while permitting simultaneous use of our balancing instrument.

EAN | Article No |

7318793784100 | 52 179-200 |

For capillary pipe with G1/16 connection.

Transition nipple

For capillary pipe with G1/16 connection.

EAN | Article No | |

R1/4xG1/16 | 7318794025509 | 52 265-306 |

Recommended together with the insulation to minimize the risk of condensation at the valve-actuator interface.M30x1,5.

Spindle extension

Recommended together with the insulation to minimize the risk of condensation at the valve-actuator interface.

M30x1,5.

Type | L | EAN | Article No |

Plastic, black | 30 | 4024052165018 | 2002-30.700 |

Female threads.Thread according to ISO 228. Thread length according to ISO 7/1.

With drain

Female threads.

Thread according to ISO 228. Thread length according to ISO 7/1.

DN | D | L | H | Kvs | Kg | EAN | Article No | |

d = G3/4 | ||||||||

15* | G1/2 | 84 | 100 | 3,5 | 0,60 | 5902276896569 | 52 849-615 | |

20* | G3/4 | 94 | 100 | 6,8 | 0,66 | 5902276896576 | 52 849-620 | |

25 | G1 | 105 | 105 | 9,8 | 0,86 | 5902276896583 | 52 849-625 | |

d = G1/2 | ||||||||

15* | G1/2 | 84 | 100 | 3,5 | 0,60 | 5902276896507 | 52 849-215 | |

20* | G3/4 | 94 | 100 | 6,8 | 0,66 | 5902276896514 | 52 849-220 | |

25 | G1 | 105 | 105 | 9,8 | 0,86 | 5902276896521 | 52 849-225 | |

→ = Flow direction

Kvs = m3/h at a pressure drop of 1 bar and fully open valve.

*) Can be connected to smooth pipes by KOMBI compression coupling.

Max.: 100°CThrust screw: AMETAL® or brass, nickel plated.Cone: Brass(For more information see catalogue leaflet KOMBI.)

KOMBI compression coupling

Max.: 100°C

Thrust screw: AMETAL® or brass, nickel plated.

Cone: Brass

(For more information see catalogue leaflet KOMBI.)

Male pipe threads on thrust screw | For pipes, diameter | EAN | Article No |

G1/2 | 10 | 7318792874901 | 53 235-109 |

G1/2 | 12 | 7318792875007 | 53 235-111 |

G1/2 | 14 | 7318792875106 | 53 235-112 |

G1/2 | 15 | 7318792875205 | 53 235-113 |

G1/2 | 16 | 7318792875304 | 53 235-114 |

G3/4 | 15 | 7318792875403 | 53 235-117 |

G3/4 | 18 | 7318792875601 | 53 235-121 |

G3/4 | 22 | 7318792875700 | 53 235-123 |

For capillary pipe with G1/16 connection.

Transition nipple

For capillary pipe with G1/16 connection.

For connection to TA valves with drain.

d | EAN | Article No |

G1/2 | 7318793660206 | 52 179-981 |

G3/4 | 7318793660305 | 52 179-986 |

Photos

52164950

Select a format Download

52265306

Select a format Download

52164100

Select a format Download

52143100

Select a format Download

52179981

Select a format Download

52163015

Select a format Download

TA-COMPACT-DP_w_pipe

Select a format Download

TA-COMPACT-DP_persp

Select a format Download

53319xxx

Select a format Download

52265212

Select a format Download

52265301

Select a format Download

52009515

Select a format Download

060102350

Select a format Download

520090xx

Select a format Download

520093xx

Select a format Download

52164210

Select a format Download

52759219

Select a format Download

52164225

Select a format Download

TA-COMPACT-DP

Select a format Download

52164220

Select a format Download

TA-COMPACT-DP_w_pipe_persp

Select a format Download