Features & Benefits

High accuracy for all settings

Ensure accurate balancing and flow reading.

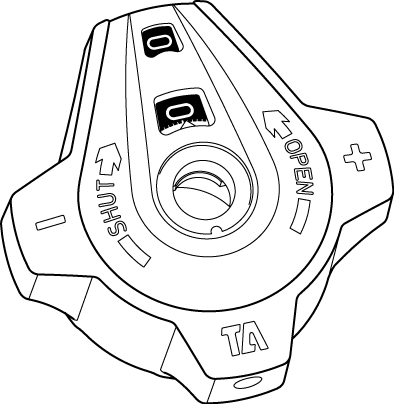

Handwheel

Equipped with a digital read-out, the handwheel ensures accurate and straightforward balancing. Positive shut-off function for easy maintenance.

Self-sealing measuring points

For simple, accurate balancing.

AMETAL®

Dezincification resistant alloy that guarantees a longer valve lifetime and lowers the risk of leakage.

Technical Information

Application:

Heating and cooling systems

Tap water systems

Functions:

Balancing

Pre-setting

Measuring

Shut-off

Draining (depending on valve type)

Dimensions:

DN 10-50

Pressure class:

PN 25

Temperature:

Max. working temperature: 120°C

(intermittent 150°C)

For higher temperatures (max. 150°C), see STAD-C.

Min. working temperature: -20°C

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Material:

Valve body and bonnet: AMETAL®

Sealing (body/bonnet): EPDM O-ring

Valve plug: AMETAL®

Seat seal: EPDM O-ring

Spindle: AMETAL®

Slip washer: PTFE

Spindle seal: EPDM O-ring

Spring: Stainless steel

Handwheel: Polyamide and TPE

Measuring points: AMETAL®

Sealings: EPDM

Caps: Polyamide and TPE

Draining: AMETAL®

Sealing: EPDM

Gaskets: Fiber-based aramid

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Marking:

Body: IMI, TA, PN 25/400 WWP, DN and inch size. DN 50 also CE.

Handwheel: TA, STAD* and DN.

Connection:

- Female thread according to ISO 228. Thread length according to ISO 7/1.

- Male thread according to ISO 228. Thread length according to DIN 3546.

Approvals:

WRAS

Articles

Female threads.Thread according to ISO 228. Thread length according to ISO 7/1.

With drain

Female threads.

Thread according to ISO 228. Thread length according to ISO 7/1.

DN | D | L | H | Kvs | Kg | EAN | Article No | |

d = G3/4 | ||||||||

10* | G3/8 | 73 | 100 | 1,36 | 0,53 | 5902276835414 | 52 851-610 | |

15* | G1/2 | 84 | 100 | 2,56 | 0,56 | 5902276835421 | 52 851-615 | |

20* | G3/4 | 94 | 100 | 5,39 | 0,64 | 5902276835438 | 52 851-620 | |

25 | G1 | 105 | 105 | 8,59 | 0,77 | 5902276835445 | 52 851-625 | |

32 | G1 1/4 | 121 | 110 | 14,2 | 1,1 | 5902276835452 | 52 851-632 | |

40 | G1 1/2 | 126 | 120 | 19,3 | 1,5 | 5902276835469 | 52 851-640 | |

50 | G2 | 155 | 120 | 32,3 | 2,1 | 5902276835476 | 52 851-650 | |

→ = Flow direction

Kvs = m3/h at a pressure drop of 1 bar and fully open valve.

*) Can be connected to smooth pipes by KOMBI compression coupling.

NOTE: In softwares (HySelect, HyTools) and balancing instrument (TA-SCOPE) the STAD, PN 25 version, is named STAD*.

Female threads.Thread according to ISO 228. Thread length according to ISO 7/1.

Without drain

Female threads.

Thread according to ISO 228. Thread length according to ISO 7/1.

DN | D | L | H | Kvs | Kg | EAN | Article No |

10* | G3/8 | 73 | 100 | 1,36 | 0,44 | 5902276835278 | 52 851-010 |

15* | G1/2 | 84 | 100 | 2,56 | 0,47 | 5902276835285 | 52 851-015 |

20* | G3/4 | 94 | 100 | 5,39 | 0,55 | 5902276835292 | 52 851-020 |

25 | G1 | 105 | 105 | 8,59 | 0,68 | 5902276835308 | 52 851-025 |

32 | G1 1/4 | 121 | 110 | 14,2 | 1,0 | 5902276835315 | 52 851-032 |

40 | G1 1/2 | 126 | 120 | 19,3 | 1,4 | 5902276835322 | 52 851-040 |

50 | G2 | 155 | 120 | 32,3 | 2,0 | 5902276835339 | 52 851-050 |

→ = Flow direction

Kvs = m3/h at a pressure drop of 1 bar and fully open valve.

*) Can be connected to smooth pipes by KOMBI compression coupling.

NOTE: In softwares (HySelect, HyTools) and balancing instrument (TA-SCOPE) the STAD, PN 25 version, is named STAD*.

Male threads.Thread according to ISO 228. Thread length according to DIN 3546.

With drain

Male threads.

Thread according to ISO 228. Thread length according to DIN 3546.

DN | D | L | H | Kvs | Kg | EAN | Article No | |

d = G3/4 | ||||||||

10 | G1/2 | 95 | 100 | 1,36 | 0,56 | 5902276836329 | 52 852-610 | |

15 | G3/4 | 108 | 100 | 2,56 | 0,61 | 5902276836336 | 52 852-615 | |

20 | G1 | 122 | 100 | 5,39 | 0,74 | 5902276836343 | 52 852-620 | |

25 | G1 1/4 | 137 | 105 | 8,59 | 1,0 | 5902276836350 | 52 852-625 | |

32 | G1 1/2 | 157 | 110 | 14,2 | 1,4 | 5902276836367 | 52 852-632 | |

40 | G2 | 166 | 120 | 19,3 | 2,1 | 5902276836374 | 52 852-640 | |

50 | G2 1/2 | 200 | 120 | 32,3 | 3,0 | 5902276836381 | 52 852-650 | |

→ = Flow direction

Kvs = m3/h at a pressure drop of 1 bar and fully open valve.

NOTE: In softwares (HySelect, HyTools) and balancing instrument (TA-SCOPE) the STAD, PN 25 version, is named STAD*.

Suitable when insulation is used.AMETAL®

Extension for measuring point M14x1

Suitable when insulation is used.

AMETAL®

d | L | EAN | Article No |

M14x1 | 71 | 7318793969507 | 52 179-016 |

Swivelling nut Max 120°CBrass/gunmetal CC491K (EN 1982)

Soldering connection

Swivelling nut

Max 120°C

Brass/gunmetal CC491K (EN 1982)

Valve DN | D | Pipe Ø | EAN | Article No |

10 | G1/2 | 10 | 7318792749100 | 52 009-510 |

10 | G1/2 | 12 | 7318792749209 | 52 009-512 |

15 | G3/4 | 15 | 7318792749308 | 52 009-515 |

15 | G3/4 | 16 | 7318792749407 | 52 009-516 |

20 | G1 | 18 | 7318792749506 | 52 009-518 |

20 | G1 | 22 | 7318792749605 | 52 009-522 |

25 | G1 1/4 | 28 | 7318792749704 | 52 009-528 |

32 | G1 1/2 | 35 | 7318792749803 | 52 009-535 |

40 | G2 | 42 | 7318792749902 | 52 009-542 |

50 | G2 1/2 | 54 | 7318792750007 | 52 009-554 |

Max 120°C (intermittent 150°C)AMETAL®/EPDM

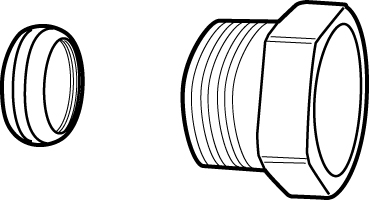

Measuring point

Max 120°C (intermittent 150°C)

AMETAL®/EPDM

L | EAN | Article No |

44 | 7318792813207 | 52 179-014 |

103 | 7318793858108 | 52 179-015 |

Can be installed without draining of the system.AMETAL®/Stainless steel/EPDM

Measuring point, extension 60 mm

Can be installed without draining of the system.

AMETAL®/Stainless steel/EPDM

L | EAN | Article No |

60 | 7318792812804 | 52 179-006 |

Identification tag

EAN | Article No |

7318792779206 | 52 161-990 |

For heating/coolingMaterial: EPPFire class: B2 (DIN 4102)Max working temperature: 120°C (intermittent 140°C)Min working temperature: 12°C, -8°C at sealed joints

Insulation

For heating/cooling

Material: EPP

Fire class: B2 (DIN 4102)

Max working temperature: 120°C (intermittent 140°C)

Min working temperature: 12°C, -8°C at sealed joints

For DN | L | H | D | B | EAN | Article No |

10-20 | 155 | 135 | 90 | 103 | 7318792839108 | 52 189-615 |

25 | 175 | 142 | 94 | 103 | 7318792839306 | 52 189-625 |

32 | 195 | 156 | 106 | 103 | 7318792839504 | 52 189-632 |

40 | 214 | 169 | 108 | 113 | 7318792839702 | 52 189-640 |

50 | 245 | 178 | 108 | 114 | 7318792839900 | 52 189-650 |

Handwheel

EAN | Article No |

7318794043503 | 52 186-007 |

Swivelling nut Max 120°CBrass/Steel 1.0045 (EN 10025-2)

Welding connection

Swivelling nut

Max 120°C

Brass/Steel 1.0045 (EN 10025-2)

Valve DN | D | Pipe DN | EAN | Article No |

10 | G1/2 | 10 | 7318792748400 | 52 009-010 |

15 | G3/4 | 15 | 7318792748509 | 52 009-015 |

20 | G1 | 20 | 7318792748608 | 52 009-020 |

25 | G1 1/4 | 25 | 7318792748707 | 52 009-025 |

32 | G1 1/2 | 32 | 7318792748806 | 52 009-032 |

40 | G2 | 40 | 7318792748905 | 52 009-040 |

50 | G2 1/2 | 50 | 7318792749001 | 52 009-050 |

For connection with press couplingSwivelling nut Max 120°CBrass/AMETAL®

Connection with smooth end

For connection with press coupling

Swivelling nut

Max 120°C

Brass/AMETAL®

Valve DN | D | Pipe Ø | EAN | Article No |

10 | G1/2 | 12 | 7318793810502 | 52 009-312 |

15 | G3/4 | 15 | 7318793810601 | 52 009-315 |

20 | G1 | 18 | 7318793810700 | 52 009-318 |

20 | G1 | 22 | 7318793810809 | 52 009-322 |

25 | G1 1/4 | 28 | 7318793810908 | 52 009-328 |

32 | G1 1/2 | 35 | 7318793811004 | 52 009-335 |

40 | G2 | 42 | 7318793811103 | 52 009-342 |

50 | G2 1/2 | 54 | 7318793811202 | 52 009-354 |

Max.: 100°CThrust screw: AMETAL® or brass, nickel plated.Cone: Brass(For more information see catalogue leaflet KOMBI.)

KOMBI compression coupling

Max.: 100°C

Thrust screw: AMETAL® or brass, nickel plated.

Cone: Brass

(For more information see catalogue leaflet KOMBI.)

Male thread on thrust screw | Ø pipe | EAN | Article No |

G3/8 | 10 | 7318792874604 | 53 235-104 |

G3/8 | 12 | 7318792874703 | 53 235-107 |

G1/2 | 10 | 7318792874901 | 53 235-109 |

G1/2 | 12 | 7318792875007 | 53 235-111 |

G1/2 | 14 | 7318792875106 | 53 235-112 |

G1/2 | 15 | 7318792875205 | 53 235-113 |

G1/2 | 16 | 7318792875304 | 53 235-114 |

G3/4 | 15 | 7318792875403 | 53 235-117 |

G3/4 | 18 | 7318792875601 | 53 235-121 |

G3/4 | 22 | 7318792875700 | 53 235-123 |

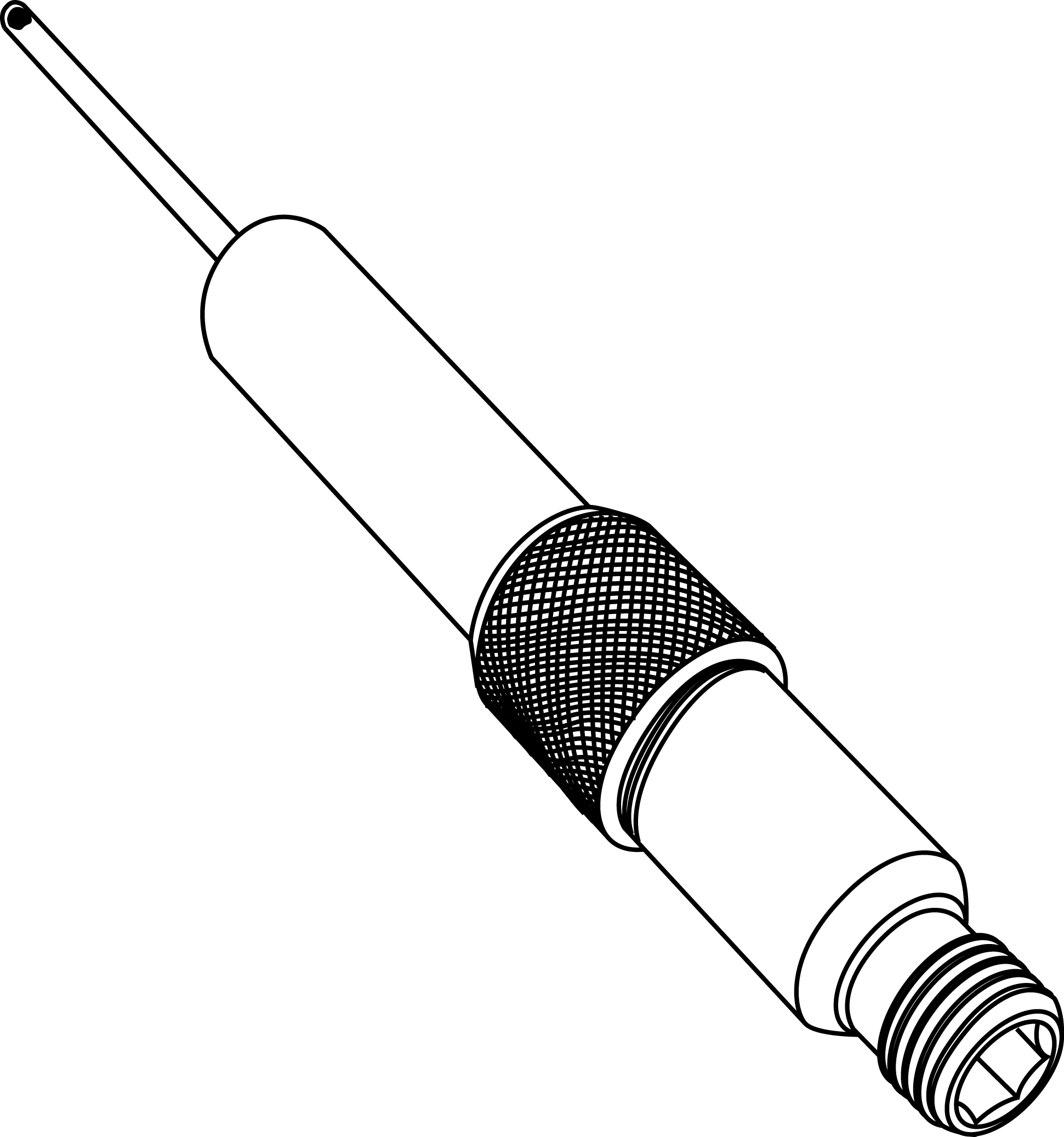

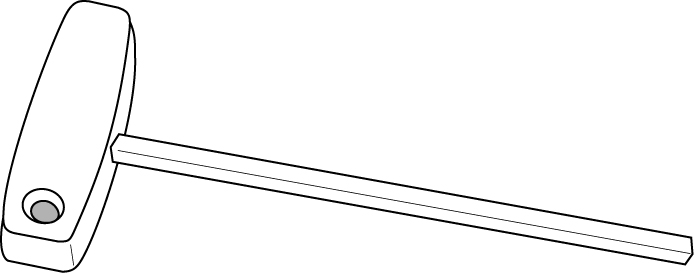

Allen key

[mm] | EAN | Article No | |

3 | Pre-setting | 7318792836008 | 52 187-103 |

5 | Draining | 7318792836107 | 52 187-105 |

Max 100°C

Compression connection

Max 100°C

Brass/AMETAL®

Support bushes shall be used, for more information see catalogue leaflet FPL.

Valve DN | D | Pipe Ø | EAN | Article No |

10 | G1/2 | 10 | 7318793620101 | 53 319-210 |

10 | G1/2 | 12 | 7318793620200 | 53 319-212 |

10 | G1/2 | 15 | 7318793620309 | 53 319-215 |

10 | G1/2 | 16 | 7318793620408 | 53 319-216 |

15 | G3/4 | 22 | 7318793705204 | 53 319-622 |

Photos

STAD_w_drain

Select a format Download

STADA_w_drain

Select a format Download

52179006

Select a format Download

52179016

Select a format Download

STAD_w-o_drain

Select a format Download

STAD_w-o_drain_persp

Select a format Download

52187103

Select a format Download

520093xx

Select a format Download

52179014

Select a format Download

520093xx_persp

Select a format Download

STADA_w_drain_persp

Select a format Download

52009515

Select a format Download

52161990

Select a format Download

52179990

Select a format Download

Handwheel_red_2-3

Select a format Download

53319xxx

Select a format Download

STAD_w_drain_persp

Select a format Download

Handwheel_red_0-0

Select a format Download

52187105

Select a format Download

Handwheel_red_4-0

Select a format Download

52179015

Select a format Download

52187103_52187105

Select a format Download

520090xx

Select a format Download