Answer your customers' frequently asked questions

Heat Pumps

What does my customer need to consider before installing a heat pump system for heating and cooling?

Before installing a heat pump system for heating and cooling, there are important considerations that your customer needs to be aware of:

Space: Ensure sufficient outdoor space for the heat pump unit. Proper clearance and airflow are crucial for optimal performance.

Power Supply: Verify if the electrical system can handle the heat pump's power requirements. If necessary, recommend any required upgrades.

Ductwork (if applicable): If existing ductwork will be used, ensure its condition. Alternatively, discuss the flexibility of ductless options.

Insulation and Sealing: Emphasize the importance of good insulation and sealing to enhance efficiency by retaining treated air and reducing energy consumption.

Climate Considerations: Discuss how different heat pump models cater to various climates. Suggest selecting a model suitable for the region or advise seeking expert guidance.

Professional Installation: Stress the significance of hiring a certified HVAC professional for safe, efficient, and compliant installation. Explain why a professional's expertise is invaluable.

Permits and Regulations: Highlight the necessity of checking local regulations for required permits or approvals. Mention that adhering to guidelines ensures a smooth installation process.

Before proceeding, it can be crucial for HVAC installers like yourself to collaborate with an HVAC professional specialising in heat pump installations. This partnership becomes particularly essential if you lack the necessary experience or expertise to offer comprehensive guidance to your customers. Working alongside a heat pump specialist ensures that your customers receive accurate and informed support throughout the installation process.

Can heat pumps be installed in radiator applications?

Yes, heat pumps can be installed in radiator applications. However, it’s important to consider that heat pump efficiency (COP) is optimised in low temperature applications. To achieve the same power output at lower temperatures requires higher flow rates and larger radiator surface areas to effectively transfer heat. Thankfully, modern well-insulated houses have lower power requirements, and therefore existing radiator systems, which are usually oversized to begin with, are still appropriate to meet the flow requirements of the new setup.

To ensure the optimal approach for your customer’s installation, we highly recommend utilising the user-friendly Hytools app to help you confidently determine the appropriate radiator size, power output, and flow requirements for the property’s specific needs.

Can I utilise individual room temperature controls without compromising the efficiency of the heat pump?

For maintaining a stable operating temperature and ensuring comfortable room temperatures, it is recommended to incorporate a buffer tank between the heat pump and the home heating circuit. Installing a properly adjusted TA STAD balancing valve between the buffer tank and the heat pump ensures a perfectly balanced flow. The puffer tank effectively compensates for variable flow rates to the rooms, enhancing overall system efficiency.

Pressurisation

Why should my customer invest in a high-quality expansion vessel?

Poor pressurisation has serious and expensive consequences. Therefore, it is financially worthwhile to invest in high-quality vessels rather than bearing the costs of equipment repairs and high energy bills.

When you choose an IMI Pneumatex vessel, you are investing in the reliability of the butyl bag, which boasts the lowest gas diffusion rate in the market. This ensures long-lasting pressurisation performance.

Our measurements have shown that an IMI Pneumatex vessel loses the same pre-set pressure that competitors lose in 1 year, in almost 10 years! By selecting an IMI Pneumatex vessel, your customers can have peace of mind knowing that their equipment is durable and their HVAC system is well-protected. As an installer, the robustness of these vessels safeguards your reputation and ensures that you won’t waste time on periodic product replacements, callbacks or unnecessary repairs.

Water Quality

Why should my customer invest in vacuum degassers instead of just air vents?

Due to the growing use of heat pumps and underfloor heating, HVAC systems now operate at lower temperatures, leading to increased adhesion between air and water molecules. Removing air from the system under these conditions becomes challenging due to the spiral construction of underfloor heating systems, which prevents air from rising and accumulating at the surface. As a result, conventional separators such as air vents or microbubble separators are mostly ineffective.

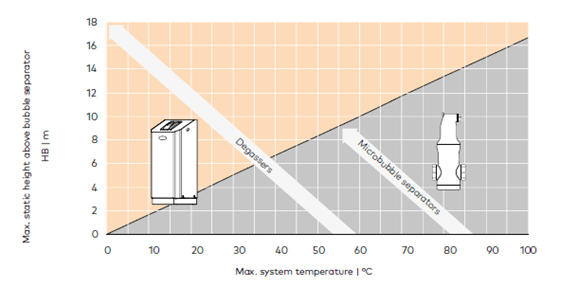

Below, you can see the conditions in which degassers are preferable to separators:

The lower the temperature or the static height, the more air will be trapped into the molecule and therefore degassers are the only effective method to remove air, which employ under-saturation to release dissolved gas. A notable advantage of this method is that the water, because it is continuously under-saturated, displays a strong affinity for air and will attempt to capture it whenever it encounters it as it circulates through the system. Well-designed vacuum degassing equipment can effectively degas the entire system within two weeks, even in large-volume applications. To prevent air from continually flowing into the system through the make-up water, it is essential that the vacuum degasser also integrates the make-up management, so that air can be degassed before it is loaded into the system.

Why should my customer invest in high-quality dirt separators, instead of cheap solutions?

The presence of dirt leads to several negative consequences for homeowners:

- Reduced indoor comfort

Dirt creates an insulating effect, impairing effective heat transfer and preventing terminal units from delivering the desired temperature, thereby affecting overall indoor comfort. - Increased energy costs

Decreased heat transfer results in reduced energy efficiency. Even a single millimeter of scale deposit can increase boiler energy consumption by up to 9%. - Shortened system service life and costly repairs

Corrosion damages expensive metal equipment, while magnetite and dirt particles circulate in the system, accumulating in valves and pumps and causing blockages, failures, and ultimately expensive premature repairs.

Cheap separators typically have filters that cannot capture small dirt particles, which are often responsible for causing significant damage. Additionally, they are equipped with low-quality magnets or lack them entirely, making them ineffective at capturing magnetite.

High-quality separators swiftly remove dirt before it can circulate and cause damage. They are cleverly designed to capture even the smallest particles (5-10 um) and feature strong magnets. Their engineering prevents clogging and blockages, maintaining optimal flow, preventing resistance and pressure drops, and ultimately enhancing energy efficiency while preventing ruptures and leaks. Considering the short-term and long-term issues caused by dirt in HVAC systems, it is financially worthwhile to invest in quality equipment rather than bearing the costs of equipment repairs and high energy bills. Prevention is always better than expensive remedies!

Hydronic Balancing

How do window replacements and insulation installations impact hydronic balancing?

Replacing windows and installing insulation directly impact the heat gain or loss properties of a home, altering the thermal needs and required load for each terminal unit, which in turn changes the design flow requirement for radiators or underfloor heating. To maintain proper hydronic balancing, adjustments may be necessary within the HVAC system. This could involve modifying the flow rate in specific zones or adjusting temperature setpoints accordingly. Moreover, it may be crucial to upgrade or replace specific HVAC components, such as control valves, to ensure the system effectively adjusts to changes in the building envelope and avoids unnecessary energy loss.

Why do some room radiators feel warm while others remain cold?

In a heating system, water naturally takes the path of least resistance. Without proper hydronic balancing, excessive flow goes to radiators in rooms near the heat source, causing overheating, while rooms farther away receive insufficient flow, resulting in uneven temperatures and uncomfortable indoor climates. Imbalanced systems not only cause discomfort but also affect maintenance and energy costs. A mere 1°C deviation from the desired room temperature (whether too high for heating or too low for cooling) can lead to energy wastage of up to 11%!

Moreover, quick fixes like installing larger pumps or raising the supply temperature only exacerbate the problem, leading to issues like noisy pipes, greater energy expenses, and compromised heat distribution.

Maintaining the appropriate balance in your customer’s system is key for achieving consistent temperature distribution throughout the property and preventing customer complaints and callbacks.

How can balancing reduce energy consumption and lower customer’s heating bills?

Proper heat distribution in a system can lower the average temperature. With each degree of temperature reduction, the property’s energy consumption decreases by approximately 6% to 11%.

Balancing techniques often lead to significant energy savings, typically ranging from 20% to 35%.

The payback period for such investments is usually between six months and a year. A 2022 independent study conducted by WaterBalans in the Netherlands analysed 700 recently upgraded homes.

These homes were equipped with Eclipse TRVs (Thermostatic Radiator Valves), Thermostatic K-heads, and underwent hydronic balancing. The study demonstrated an average energy savings of 27%.

Notably, a subset of homes that made lifestyle changes, such as unblocking radiators and adjusting K-heads to setting #3, achieved even higher energy savings, up to 50%. Correctly balanced systems not only consume less energy but also enhance tenant comfort, improving their overall quality of life.

Why is my customer’s HVAC system making noise?

System noise can be highly disruptive and is often caused by vibrations in valves and pipework. This can be attributed to:

∙ Air and dirt circulating in radiators and pipes

∙ High flow speed

∙ Excessive pressure drop in valves

Air vents, dirt separation, and degassing solutions help maintain a clean system and prevent the formation of air bubbles that can contribute to system noise when passing through valves and radiators. Additionally, implementing balancing techniques will optimise pressure drops in the system, effectively avoiding excessive pressure drops across valves. These solutions not only result in a quieter HVAC system but also enhance its overall performance and efficiency, creating a high-performing heating and cooling system.

Thermostatic & Room Control

Why do radiator thermostatic valves get stuck, how can they be easily repaired, and what preventive measures can be taken?

IMI Heimeier Radiator Thermostatic Valves (TRVs) do not stick, but it can happen with valves from other manufacturers due to various factors.

Understanding how they work can help in their repair and prevention. A TRV consists of a control valve (radiator valve/valve base) and a controller (thermostatic head/upper part). It operates based on the surrounding temperature (room temperature), regulating the flow independently without external energy requirements. A thermostatic head contains an expansion element (liquid, wax, or gas) that expands or contracts with the room temperature. This element applies pressure on the valve spindle and the valve cone, which closes the valve when the desired temperature is reached and opens it again when the temperature falls below the set point. A mechanical spring assists in the opening and closing process, with its strength determined by the type of expansion element used.

During the summer months when the heating system is usually off, the thermostatic head may remain set at a specific temperature (e.g., 20°C). This can lead to the valve remaining closed throughout the summer, causing the valve spindle and cone to become stagnant. Dirt, lime, magnetite, and rust can accumulate on the surfaces of the valve spindle and cone during this period. As a result, the mechanical spring may no longer be able to open the valve, leaving the affected rooms cold.

To prevent radiator valves from sticking, it is recommended to periodically operate the radiator thermostat head during the summer and keep it fully open if possible (position #5). Regularly actuating the valve spindle and cone makes it difficult for dirt and deposits to adhere strongly, minimising the chances of valve sticking.

How can customers save energy without replacing old radiators?

To enhance energy savings in existing systems, along with effective air and dirt removal and hydraulic balancing, replacing old thermostatic radiator heads is the simplest, yet most powerful, solution.

By upgrading to new thermostatic heads, energy consumption can be reduced by 28% compared to manual ones.

IMI Heimeier Thermostatic Head K comes with energy-saving clips for added convenience and efficiency:

The blue energy-saving clip limits the lower temperature setting, such as the night setting.

The blue energy-saving clip limits the lower temperature setting, such as the night setting.

The red energy-saving clip restricts the upper temperature range and prevents accidental high temperature adjustments.

These clips also prove highly practical during room ventilation. By retracting the blue clip, the thermostatic head can be temporarily set to 0 without losing the preferred temperature range.

System renovation

If a client asks if they should replace their entire HVAC system, what could you respond?

When a client inquires about the possibility of replacing their entire HVAC system, it's essential to provide an informed response based on a comprehensive assessment of their current system. You should evaluate factors such as the system's age, efficiency, and overall condition. This assessment enables you to make a well-informed recommendation regarding the potential replacement of their HVAC system or the option to upgrade specific components. Your guidance should consider their system's performance, potential repair costs, and the long-term benefits of enhanced energy efficiency. Ultimately, your response should be tailored to their unique needs and budget constraints, with a focus on delivering the best solution for their specific situation.

How often should I maintain my HVAC system for optimal performance?

It's essential to guide your customers on the ideal maintenance schedule. This strategic approach allows them to prepare their systems for extreme weather conditions before they become too hot or cold. By emphasizing the importance of regular maintenance, you can help prevent potential issues that might lead to system failures when they're needed most.

Spring HVAC Maintenance:

In the spring, prioritize maintenance for air conditioning systems. Encourage your customers to clean the evaporator coils and condenser coils, ensuring they are free from dirt and debris. This step is crucial for maintaining the efficiency of their cooling systems.

Fall HVAC Maintenance:

As the colder months approach, shift your focus to heating systems. Advise your clients to inspect fuel line connections, gas pressure, burner combustion, and heat exchangers to ensure they are in optimal working condition. This thorough examination will help guarantee the reliability and efficiency of their heating systems throughout the winter.

What HVAC maintenance can I perform myself?

As HVAC professionals, it is key to educate homeowners about the HVAC maintenance tasks they can handle independently. While many aspects of HVAC maintenance require professional expertise, there are some routine tasks homeowners can perform to keep their systems running efficiently.

Regular Filter Replacement: Encourage homeowners to regularly change or clean the air filters in their HVAC system. This is a simple but vital task that can enhance system efficiency and indoor air quality. Explain the importance of using the right filter type and changing them according to manufacturer recommendations.

Thermostat Settings: Teach homeowners how to use their programmable thermostats efficiently. Advise them on setting appropriate temperature schedules to reduce energy consumption when they're away or sleeping. Explain the benefits of upgrading to a smart thermostat for enhanced control.

Condenser and Evaporator Cleaning: Instruct homeowners on cleaning the area around the outdoor condenser unit. They should remove debris, leaves, and dirt that may obstruct airflow. For the indoor unit, guide them on keeping the area clean and free from obstructions to maintain proper airflow.

Sealing Leaks and Insulating: Encourage homeowners to inspect their ductwork for leaks and seal them if necessary. Additionally, suggest they check the insulation in their home, especially in attics and crawl spaces, to ensure it's sufficient for energy efficiency.

Routine Visual Inspection: Homeowners can perform visual inspections to identify any unusual sounds, leaks, or visible damage to their HVAC system. They should be advised to contact a professional if they notice any problems.

Maintenance Agreements: Recommend homeowners to consider maintenance agreements with a professional HVAC service provider. These agreements typically include annual or biannual inspections and tune-ups, which are essential for long-term system health.

By educating homeowners about these self-maintenance tasks, you can empower them to take a proactive role in ensuring the efficiency and longevity of their HVAC systems. Emphasize the importance of professional maintenance at least once a year to address more complex issues and keep the system in optimal condition. This collaborative approach can lead to better-performing HVAC systems and satisfied homeowners.