Features & Benefits

Handwheel

Equipped with a digital read-out, the handwheel ensures accurate and straightforward balancing.

Handwheel for DN 65-150 with side reading makes the read-out easy from any angle.

Accurate and precise

Provides high accuracy of measurement.

Self-sealing measuring points

For simple, accurate balancing.

Positive shut-off function

For easy maintenance.

Technical Information

Applications:

Heating and cooling systems.

Functions:

Balancing

Presetting

Measuring

Shut-off (The balancing cone for valves DN 100-400 is pressure released).

Dimensions:

STAF: DN 65-150

STAF-SG: DN 20-400

Pressure class:

STAF: PN 16

STAF-SG: PN 16 and PN 25 (see each product)

Temperature:

Max. working temperature: 120°C

Min. working temperature: -10°C

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Material:

Body, STAF: Cast iron EN-GJL-250 (GG 25).

Body, STAF-SG: Ductile iron EN-GJS-400-15.

DN 20-150:

Bonnet, cone and spindle of AMETAL®.

DN 200-300:

Bonnet and cone of ductile iron EN-GJS-400-15, and spindle of AMETAL®.

DN 350-400:

CE marked products: Bonnet of ductile iron EN-GJS-400-15, cone of ductile iron EN-GJS-400-15 and gunmetal CuSn5Zn5Pb5 (EN 1982), and spindle of AMETAL®.

Not CE marked products: Bonnet of ductile iron EN-GJS-400-15, cone of silicon brass CuZn16Si4-C (EN 1982) and gunmetal CuSn5Zn5Pb5 (EN 1982), and spindle of AMETAL®.

Cone DN 100-400: PTFE coated.

Seals: EPDM.

Slip washer: PTFE.

Bonnet bolts: Surface treated steel.

Measuring points: AMETAL® and EPDM.

Handwheel: DN 20-50 polyamide and TPE, DN 65-150 polyamide, DN 200-400 aluminium.

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Surface treatment:

DN 20-200: Epoxy painting.

DN 250-400: Duasolid painting.

Marking:

Body: TA, PN, DN, flow direction arrow, material and casting date (year, month, day).

CE-marking:

CE: STAF (PN 16) DN 65-150, STAF-SG (PN 16) DN 200, STAF-SG (PN 25) DN 50-125.

CE 0409*: STAF-SG (PN 16) DN 250-400, STAF-SG (PN 25) DN 150-400.

*) Notified body.

Flanges:

ISO 7005-2, EN 1092-2.

Face to face length:

ISO 5752 series 1, EN 558-1 series 1.

Articles

Bolted bonnet

Spindle extension for DN 65-150 is included.

PN 16, ISO 7005-2, EN 1092-2

DN | Number of bolt holes | D | L | H | H 1) | Kvs | Kg | EAN | Article No |

65 | 4 | 185 | 290 | 163 | 223 | 85 | 10,0 | 5902276805134 | 52 186-065 |

80 | 8 | 200 | 310 | 172 | 232 | 123 | 12,4 | 5902276805141 | 52 186-080 |

100 | 8 | 220 | 350 | 223 | 283 | 185 | 17,9 | 5902276805158 | 52 186-090 |

125 | 8 | 250 | 400 | 259 | 319 | 294 | 25,5 | 5902276805165 | 52 186-091 |

150 | 8 | 285 | 480 | 273 | 333 | 400 | 35,0 | 5902276805172 | 52 186-092 |

1) Height with spindle extension

→ = Flow direction

Kvs = m3/h at a pressure drop of 1 bar and fully open valve.

NOTE: In softwares (HySelect, HyTools) and balancing instrument (TA-SCOPE) the STAF/STAF-SG, DN 65-150, is named STAF* resp. STAF-SG*.

Measuring points on body

Bolted bonnet

Measuring points on body

PN 16, ISO 7005-2, EN 1092-2

DN | Number of bolt holes | D | L | H | Kvs | Kg | EAN | Article No | |

200 | 12 | 340 | 600 | 430 | 765 | 76 | 7318792823800 | 52 181-093 | |

250 | 12 | 400 | 730 | 420 | 1185 | 122 | 7318792823909 | 52 181-094 | |

300 | 12 | 455 | 850 | 480 | 1450 | 163 | 7318792824005 | 52 181-095 | |

350 | 16 | 520 | 980 | 585 | 2200 | 287 | 7318793859402 | 52 181-096 | |

400 | 16 | 580 | 1100 | 640 | 2780 | 391 | 7318793859303 | 52 181-097 | |

Not CE marked products * | |||||||||

350 | 16 | 520 | 980 | 585 | 2200 | 297 | 7318794004603 | 52 181-196 | |

400 | 16 | 580 | 1100 | 640 | 2780 | 406 | 7318794004702 | 52 181-197 | |

PN 25, ISO 7005-2, EN 1092-2

DN | Number of bolt holes | D | L | H | Kvs | Kg | EAN | Article No | |

200 | 12 | 360 | 600 | 430 | 765 | 76 | 7318792826702 | 52 182-093 | |

250 | 12 | 425 | 730 | 420 | 1185 | 122 | 7318792826801 | 52 182-094 | |

300 | 16 | 485 | 850 | 480 | 1450 | 163 | 7318792826900 | 52 182-095 | |

350 | 16 | 555 | 980 | 585 | 2200 | 287 | 7318793843401 | 52 182-096 | |

400 | 16 | 620 | 1100 | 640 | 2780 | 391 | 7318793843500 | 52 182-097 | |

Not CE marked products * | |||||||||

350 | 16 | 555 | 980 | 585 | 2200 | 297 | 7318794004801 | 52 182-196 | |

400 | 16 | 620 | 1100 | 640 | 2780 | 406 | 7318794004900 | 52 182-197 | |

*) NOTE: Not allowed to be installed in EU or EFTA countries.

→ = Flow direction

Kvs = m3/h at a pressure drop of 1 bar and fully open valve.

Threaded bonnet

PN 25, ISO 7005-2, EN 1092-2 (DN 20-50 also fit PN 16 flanges)

DN | Number of bolt holes | D | L | H | Kvs | Kg | EAN | Article No |

20 | 4 | 105 | 150 | 100 | 5,7 | 2,3 | 7318792825705 | 52 182-020 |

25 | 4 | 115 | 160 | 109 | 8,7 | 2,9 | 7318792825804 | 52 182-025 |

32 | 4 | 140 | 180 | 111 | 14,2 | 4,3 | 7318792825903 | 52 182-032 |

40 | 4 | 150 | 200 | 122 | 19,2 | 5,2 | 7318792826009 | 52 182-040 |

50 | 4 | 165 | 230 | 122 | 33 | 6,6 | 7318792826108 | 52 182-050 |

Bolted bonnet

Spindle extension for DN 65-150 is included.

PN 25, ISO 7005-2, EN 1092-2

DN | Number of bolt holes | D | L | H | H 1) | Kvs | Kg | EAN | Article No |

65 | 8 | 185 | 290 | 163 | 223 | 85 | 10,0 | 5902276805233 | 52 187-065 |

80 | 8 | 200 | 310 | 172 | 232 | 123 | 12,4 | 5902276805240 | 52 187-080 |

100 | 8 | 235 | 350 | 223 | 283 | 185 | 17,9 | 5902276805257 | 52 187-090 |

125 | 8 | 270 | 400 | 259 | 319 | 294 | 25,5 | 5902276805264 | 52 187-091 |

150 | 8 | 300 | 480 | 273 | 333 | 400 | 35,0 | 5902276805271 | 52 187-092 |

1) Height with spindle extension

NOTE: In softwares (HySelect, HyTools) and balancing instrument (TA-SCOPE) the STAF/STAF-SG, DN 65-150, is named STAF* resp. STAF-SG*.

For older STAD and STAFMax 150°CAMETAL®/EPDM

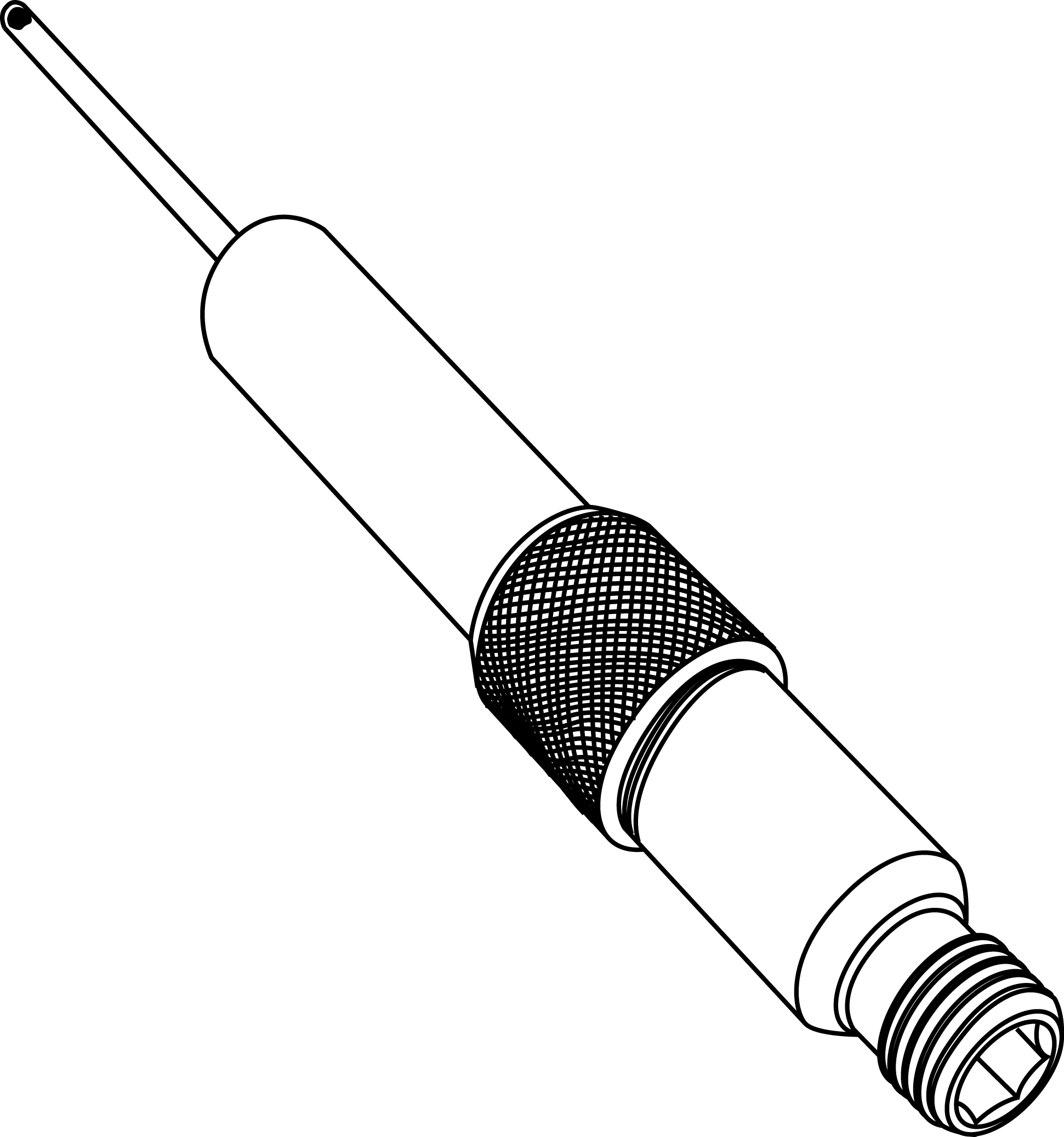

Measuring point

For older STAD and STAF

Max 150°C

AMETAL®/EPDM

d | L | EAN | Article No | |

DN 20-50 | ||||

R1/4 | 30 | 7318792812408 | 52 179-000 | |

R1/4 | 90 | 7318792814303 | 52 179-601 | |

DN 65-400 | ||||

R3/8 | 30 | 7318792812903 | 52 179-007 | |

R3/8 | 90 | 7318792814402 | 52 179-607 | |

(not for 52 179-000/-601)Can be installed without draining of the system.AMETAL®/Stainless steel/EPDM

Measuring point, extension 60 mm

(not for 52 179-000/-601)

Can be installed without draining of the system.

AMETAL®/Stainless steel/EPDM

L | EAN | Article No |

60 | 7318792812804 | 52 179-006 |

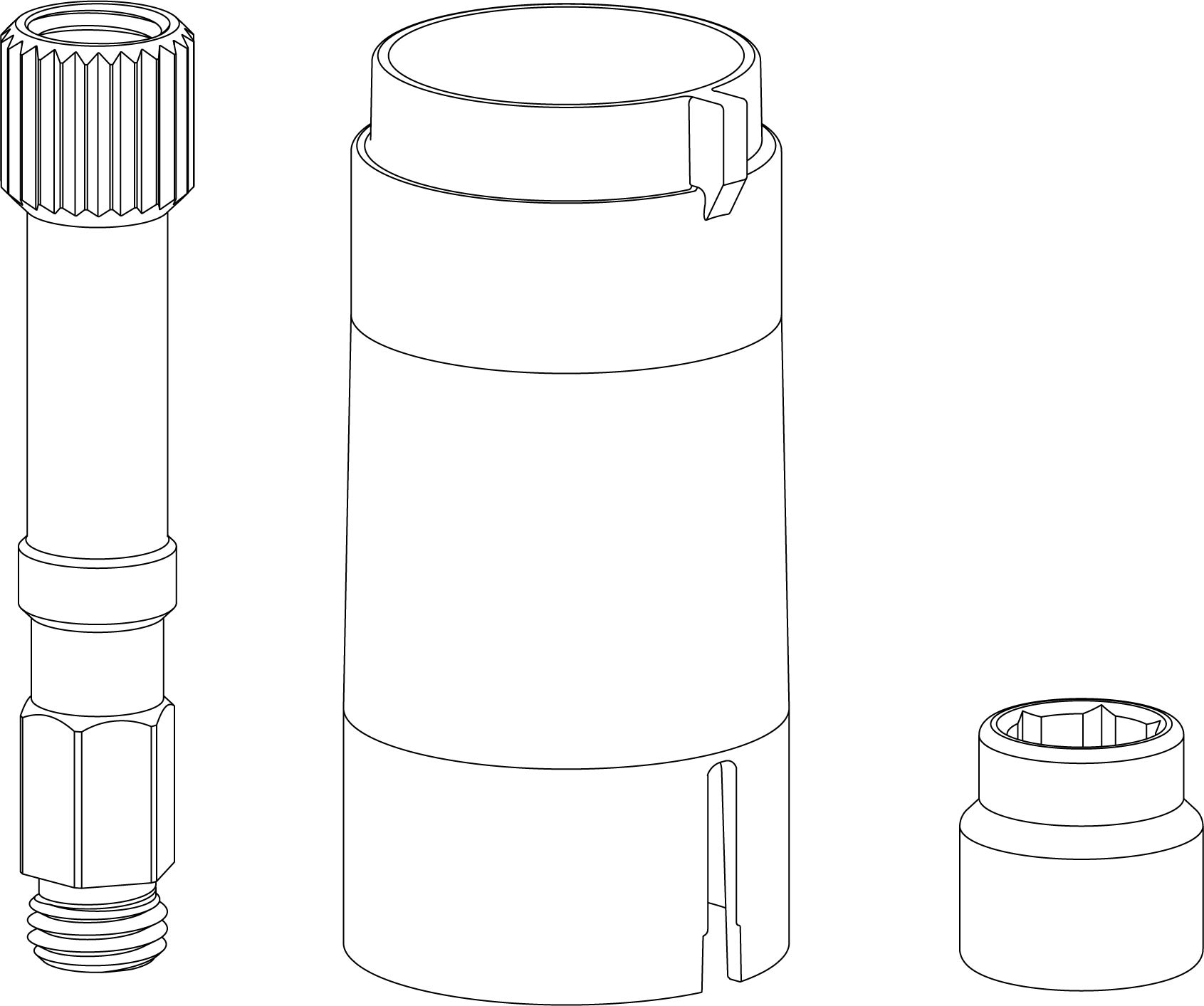

Handwheel

DN | EAN | Article No |

20-50 | 7318794043503 | 52 186-007 |

65-150 | 5902276808968 | 52 186-010 |

200-400 | 7318792835001 | 52 186-004 |

For heating/coolingMaterial: EPPFire class: B2 (DIN 4102)Max working temperature: 120°C (intermittent 140°C)Min working temperature: 12°C, -8°C at sealed joints

Insulation

For heating/cooling

Material: EPP

Fire class: B2 (DIN 4102)

Max working temperature: 120°C (intermittent 140°C)

Min working temperature: 12°C, -8°C at sealed joints

For DN | L | D | C | EAN | Article No |

50 | 390 | 250 | 252 | 7318792840708 | 52 189-850 |

65 | 450 | 270 | 272 | 7318792840807 | 52 189-865 |

80 | 480 | 290 | 292 | 7318792840906 | 52 189-880 |

100 | 520 | 320 | 322 | 7318792841002 | 52 189-890 |

125 | 570 | 350 | 352 | 7318792841101 | 52 189-891 |

150 | 660 | 380 | 382 | 7318792841200 | 52 189-892 |

AMETAL®/EPDM

Measuring point

AMETAL®/EPDM

d | L | EAN | Article No | |

DN 20-50 | ||||

R1/4 | 39 | 7318792813108 | 52 179-009 | |

R1/4 | 103 | 7318792814600 | 52 179-609 | |

DN 65-400 | ||||

R3/8 | 45 | 7318792813009 | 52 179-008 | |

R3/8 | 101 | 7318792814501 | 52 179-608 | |

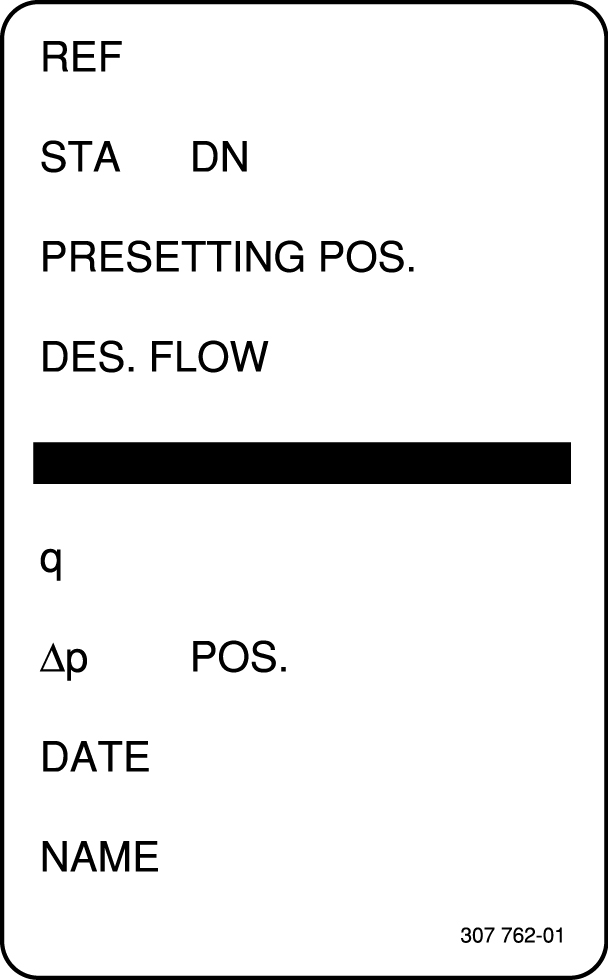

Allen key

For locking of setting.

[mm] | For DN | EAN | Article No |

3 | 20-150 | 7318792836008 | 52 187-103 |

5 | 200-400 | 7318792836107 | 52 187-105 |

Identification tag

EAN | Article No |

7318792779206 | 52 161-990 |

Spare part.Included in valves DN 65-150.Needed on DN 65-80 when using TA prefab insulations (52 189-8xx).

Spindle extension

Spare part.

Included in valves DN 65-150.

Needed on DN 65-80 when using TA prefab insulations (52 189-8xx).

For DN | EAN | Article No |

65-150 | 5902276808951 | 52 186-015 |

Photos

media:m_product_photo:abb2a929-0be0-4327-b3e4-e7bf56d28533

Select a format Download

STAF_DN80_PN16_persp

Select a format Download

STAF_DN100-150_PN16_persp

Select a format Download

STAF-SG_DN100-150_persp

Select a format Download

STAF_DN65_PN16_persp

Select a format Download

STAF-SG_DN65-80_PN25_persp

Select a format Download

STAF_DN100-150_PN16

Select a format Download

STAF-SG_DN65-80_PN25

Select a format Download

STAF-SG_DN20-50_persp

Select a format Download

STAF-SG_DN200-400

Select a format Download

STAF_DN65_PN16

Select a format Download

STAF_DN80_PN16

Select a format Download