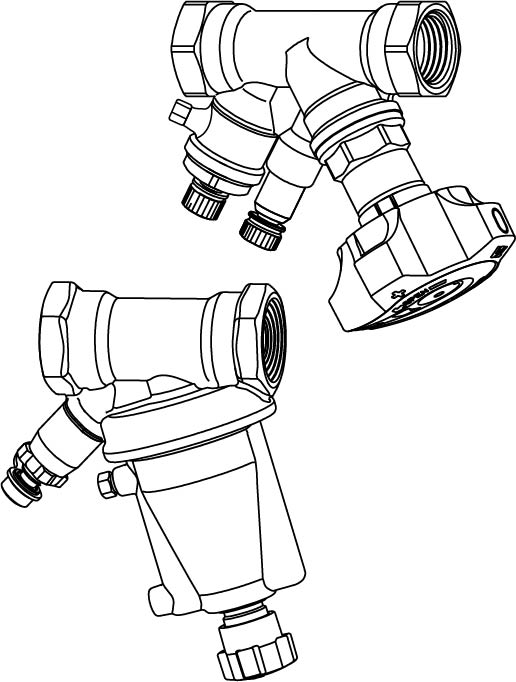

Features & Benefits

Pressure relief cone

Ensures accurate differential pressure control.

Adjustable set-point and shut-off function

Delivers desired differential pressure ensuring accurate balancing. Shut-off function makes maintenance easy and straightforward.

Measuring point with drain option

Simplifies the balancing procedure, and increases its accuracy.

Technical Information

Application:

Heating and cooling systems.

Functions:

Differential pressure control

Adjustable Δp

Measuring point

Shut-off

Draining (accessory)

Dimensions:

DN 15-50

Pressure class:

PN 16

Max. differential pressure (ΔpV):

250 kPa

Setting range:

DN 15 LF: 5* - 25 kPa

DN 15 - 20: 5* - 25 kPa

DN 32 - 40: 10* - 40 kPa

DN 15 LF: 10* - 60 kPa

DN 15 - 25: 10* - 60 kPa

DN 32 - 50: 20* - 80 kPa

*) Delivery setting

LF = Low flow

Temperature:

Max. working temperature: 120°C

Min. working temperature: -20°C

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Material:

Valve body: AMETAL®

Bonnet: AMETAL®

Cone: AMETAL®

Spindles: AMETAL®

O-rings: EPDM rubber

Membrane: HNBR rubber

Spring: Stainless steel

Spring support: AMETAL® and reinforced PPS

Handwheel: Polyamide

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Marking:

Body: IMI or TA, PN 16/150, DN, inch size and flow direction arrow.

Bonnet: STAP, ΔpL 5-25, 10-40, 10-60 or 20-80.

Connection:

Internal thread according to ISO 228, thread length according to ISO 7-1.

Articles

1 m capillary pipe and transition nipples G1/2 and G3/4 are included.

Internal threads

1 m capillary pipe and transition nipples G1/2 and G3/4 are included.

DN | D | L | H | W | Kvm | qmax [m3/h] | Kg | EAN | Article No | |

5-25 kPa | ||||||||||

15* LF | G1/2 | 84 | 137 | 72 | 0,7 | 0,5 | 1,1 | 5902276821271 | 52 264-115 | |

15* | G1/2 | 84 | 137 | 72 | 1,4 | 1,0 | 1,1 | 7318793946607 | 52 265-115 | |

20* | G3/4 | 91 | 139 | 72 | 3,1 | 2,2 | 1,2 | 7318793946706 | 52 265-120 | |

10-40 kPa | ||||||||||

32 | G1 1/4 | 133 | 179 | 110 | 8,5 | 6,0 | 2,6 | 7318793790002 | 52 265-132 | |

40 | G1 1/2 | 135 | 181 | 110 | 12,8 | 9,1 | 2,9 | 7318793790101 | 52 265-140 | |

10-60 kPa | ||||||||||

15* LF | G1/2 | 84 | 137 | 72 | 0,7 | 0,5 | 1,1 | 5902276821264 | 52 264-015 | |

15* | G1/2 | 84 | 137 | 72 | 1,4 | 1,0 | 1,1 | 7318793623201 | 52 265-015 | |

20* | G3/4 | 91 | 139 | 72 | 3,1 | 2,2 | 1,2 | 7318793623300 | 52 265-020 | |

25 | G1 | 93 | 141 | 72 | 5,5 | 3,9 | 1,3 | 7318793623409 | 52 265-025 | |

20-80 kPa | ||||||||||

32 | G1 1/4 | 133 | 179 | 110 | 8,5 | 6,0 | 2,6 | 7318793623805 | 52 265-032 | |

40 | G1 1/2 | 135 | 181 | 110 | 12,8 | 9,1 | 2,9 | 7318793623904 | 52 265-040 | |

50 | G2 | 137 | 187 | 110 | 24,4 | 17,3 | 3,5 | 7318793624000 | 52 265-050 | |

→ = Flow direction

LF = Low flow

Kvm = m3/h at a pressure drop of 1 bar and maximum opening corresponding to the p-band (-20% respectively -25%).

*) Can be connected to smooth pipes by KOMBI compression coupling. See accessories or catalogue leaflet KOMBI.

G = Thread according to ISO 228. Thread length according to ISO 7-1.

For more information on STAD see separate catalogue leaflet

STAP/STAD package

For more information on STAD see separate catalogue leaflet

STAP DN | STAD DN | EAN | Article No |

5-25 kPa | |||

15 LF | 10 | 5902276822315 | 52 864-301 |

15 LF | 15 | 5902276822322 | 52 864-302 |

15 | 15 | 7318794042001 | 52 865-101 |

20 | 20 | 7318794042100 | 52 865-102 |

10-40 kPa | |||

32 | 32 | 7318794042209 | 52 865-103 |

40 | 40 | 7318794042308 | 52 865-104 |

10-60 kPa | |||

15 LF | 10 | 5902276822339 | 52 864-111 |

15 LF | 15 | 5902276822346 | 52 864-112 |

15 | 10 | 7318794041301 | 52 865-001 |

15 | 15 | 7318794041400 | 52 865-002 |

20 | 20 | 7318794041509 | 52 865-003 |

25 | 25 | 7318794041608 | 52 865-004 |

20-80 kPa | |||

32 | 32 | 7318794041707 | 52 865-005 |

40 | 40 | 7318794041806 | 52 865-006 |

50 | 50 | 7318794041905 | 52 865-007 |

For heating/coolingMaterial: EPPFire class: B2 (DIN 4102)Max working temperature: 120°C (intermittent 140°C)Min working temperature: 12°C, -8°C at sealed joints.

Insulation

For heating/cooling

Material: EPP

Fire class: B2 (DIN 4102)

Max working temperature: 120°C (intermittent 140°C)

Min working temperature: 12°C, -8°C at sealed joints.

For DN | L | H | W | EAN | Article No |

15-25 | 145 | 172 | 116 | 7318793658906 | 52 265-225 |

32-50 | 191 | 234 | 154 | 7318793659002 | 52 265-250 |

For use on STAD or STS. Replacement of existing draining.

Connection sleeve kit for capillary pipe

For use on STAD or STS. Replacement of existing draining.

EAN | Article No |

7318794027800 | 52 265-216 |

Measuring point STAP

EAN | Article No |

7318793660602 | 52 265-205 |

Draining kit STAP

d | EAN | Article No |

G1/2 | 7318793660404 | 52 265-201 |

G3/4 | 7318793660503 | 52 265-202 |

For connection of capillary pipe while permitting simultaneous use of our balancing instrument.

Measuring point, two-way

For connection of capillary pipe while permitting simultaneous use of our balancing instrument.

EAN | Article No |

7318793784100 | 52 179-200 |

See catalogue leaflet KOMBI.

Compression connection KOMBI

See catalogue leaflet KOMBI.

D | Pipe Ø | EAN | Article No |

G1/2 | 10 | 7318792874901 | 53 235-109 |

G1/2 | 12 | 7318792875007 | 53 235-111 |

G1/2 | 14 | 7318792875106 | 53 235-112 |

G1/2 | 15 | 7318792875205 | 53 235-113 |

G1/2 | 16 | 7318792875304 | 53 235-114 |

G3/4 | 15 | 7318792875403 | 53 235-117 |

G3/4 | 18 | 7318792875601 | 53 235-121 |

G3/4 | 22 | 7318792875700 | 53 235-123 |

Complete with connections for 6 mm pipe

Extension kit for capillary pipe

Complete with connections for 6 mm pipe

EAN | Article No |

7318793781505 | 52 265-212 |

Capillary pipe

L | EAN | Article No |

1 m | 7318793661500 | 52 265-301 |

For capillary pipe with G1/16 connection.

Transition nipple

For capillary pipe with G1/16 connection.

d | EAN | Article No |

G1/2 | 7318793660206 | 52 179-981 |

G3/4 | 7318793660305 | 52 179-986 |

Venting

Plug

Venting

EAN | Article No |

7318793661609 | 52 265-302 |

Photos

52265205

Select a format Download

STAP_persp_kat

Select a format Download

52265301

Select a format Download

52179986

Select a format Download

STAP_w_capillary_pipe

Select a format Download

52265250

Select a format Download

52265201

Select a format Download

52265225

Select a format Download

52179200

Select a format Download

STAP_STAD_kit

Select a format Download

52265212

Select a format Download

52265302

Select a format Download

52179981

Select a format Download

STAP

Select a format Download

STAP_STAD_kit_red

Select a format Download

52265216

Select a format Download

STAP15persp_kat

Select a format Download