Features & Benefits

Easy handling and installation

Very low weight and small overall proportions.

Precise and stable differential pressure control

Unrivaled accuracy thanks to the new PILOT technology.

Measuring and system diagnostics

Unique features to validate and better understand system behaviour to minimize energy consumption.

Technical Information

Application:

Heating and cooling systems.

Installation in the return pipe.

Functions:

Differential pressure control

Pre-setting Δp over the load (ΔpL)

Measuring (ΔpL)

Dimensions:

DN 65-200

Pressure class:

Class 150

Max. differential pressure (ΔpV):

1200 kPa

Setting range:

10* - 50 kPa

30* - 150 kPa

80* - 400 kPa

*) Delivery settings

Leakage rate:

Tight sealing

Temperature:

Max. working temperature:

- with measuring points, standard: 120°C

- with measuring points, double secured: 150°C

Min. working temperature: -10°C

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Material:

Valve body: Ductile iron EN-GJS-400-15

Pilot extension body: Brass

Pilot body: AMETAL®

O-rings: EDPM rubber

Seat seal: EPDM/Stainless steel

Plug mechanism: Stainless steel and brass

Membrane: EPDM rubber

Springs: Stainless steel

Screws and nuts: Stainless steel

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Surface treatment:

Pilot body: Non treated

Valve body: Electrophoretic painting.

Marking:

TA, IMI, DN, Class, Kvs, Tmin/max, serial number, valve body material and flow direction arrow, label, ΔpL range.

Colour identification on top of the pilot:

10 - 50 kPa: Blue

30 - 150 kPa: Orange

80 - 400 kPa: Grey

CE-marking:

DN 65 - 125: CE

DN 150 - 200: CE 1370 *

*) Notified body.

Flanges:

According to ASME/ANSI B16.42 Class 150.

Articles

Flanged

Flanges according ASME/ANSI B16.42 Class 150.

1,2 m capillary pipe (Ø6 mm), capillary pipe connection Ø6xR1/4 (separate part) + Ø6xR1/8 (mounted on valve) and capillary pipe connection with shut-off Ø6xG3/8 are included.

Class 150

DN | (size) | Number of bolt holes | D | L | H1 | H2 | Kvm | qmax [m3/h] | Kg | EAN | Article No |

10-50 kPa | |||||||||||

65 | 2 1/2" | 4 | 180 | 190 | 274 | 90 | 75 | 53 | 18 | 3831112530201 | 23121-2311-065 |

80 | 3" | 4 | 191 | 203 | 281 | 96 | 110 | 78 | 21 | 3831112530294 | 23121-2311-080 |

100 | 4" | 8 | 229 | 229 | 303 | 115 | 180 | 127 | 34 | 3831112530560 | 23121-2311-100 |

125 | 5" | 8 | 254 | 254 | 313 | 127 | 270 | 191 | 45 | 3831112530652 | 23121-2311-125 |

150 | 6" | 8 | 280 | 267 | 331 | 140 | 400 | 283 | 57 | 3831112530751 | 23121-2311-150 |

200 | 8" | 8 | 343 | 292 | 361 | 172 | 600 | 424 | 88 | 3831112530980 | 23121-2311-200 |

30-150 kPa | |||||||||||

65 | 2 1/2" | 4 | 180 | 190 | 274 | 90 | 75 | 53 | 18 | 3831112530218 | 23121-2321-065 |

80 | 3" | 4 | 191 | 203 | 281 | 96 | 110 | 78 | 21 | 3831112530300 | 23121-2321-080 |

100 | 4" | 8 | 229 | 229 | 303 | 115 | 180 | 127 | 34 | 3831112530577 | 23121-2321-100 |

125 | 5" | 8 | 254 | 254 | 313 | 127 | 270 | 191 | 45 | 3831112530676 | 23121-2321-125 |

150 | 6" | 8 | 280 | 267 | 331 | 140 | 400 | 283 | 57 | 3831112530768 | 23121-2321-150 |

200 | 8" | 8 | 343 | 292 | 361 | 172 | 600 | 424 | 88 | 3831112530997 | 23121-2321-200 |

80-400 kPa | |||||||||||

65 | 2 1/2" | 4 | 180 | 190 | 274 | 90 | 75 | 53 | 18 | 3831112530225 | 23121-2331-065 |

80 | 3" | 4 | 191 | 203 | 281 | 96 | 110 | 78 | 21 | 3831112530317 | 23121-2331-080 |

100 | 4" | 8 | 229 | 229 | 303 | 115 | 180 | 127 | 34 | 3831112530584 | 23121-2331-100 |

125 | 5" | 8 | 254 | 254 | 313 | 127 | 270 | 191 | 45 | 3831112530683 | 23121-2331-125 |

150 | 6" | 8 | 280 | 267 | 331 | 140 | 400 | 283 | 57 | 3831112530775 | 23121-2331-150 |

200 | 8" | 8 | 343 | 292 | 361 | 172 | 600 | 424 | 88 | 3831112531000 | 23121-2331-200 |

Kvm = m3/h at a pressure drop of 1 bar and maximum opening corresponding to the p-band.

Flanged

Flanges according ASME/ANSI B16.42 Class 150.

1,2 m capillary pipe (Ø6 mm), capillary pipe connection Ø6xR1/4 (separate part) + Ø6xR1/8 (mounted on valve) and capillary pipe connection with shut-off Ø6xG3/8 are included.

Class 150

DN | (size) | Number of bolt holes | D | L | H1 | H2 | Kvm | qmax [m3/h] | Kg | EAN | Article No |

10-50 kPa | |||||||||||

65 | 2 1/2" | 4 | 180 | 190 | 274 | 90 | 75 | 53 | 18 | 3831112531079 | 23121-2312-065 |

80 | 3" | 4 | 191 | 203 | 281 | 96 | 110 | 78 | 21 | 3831112531154 | 23121-2312-080 |

100 | 4" | 8 | 229 | 229 | 303 | 115 | 180 | 127 | 34 | 3831112531246 | 23121-2312-100 |

125 | 5" | 8 | 254 | 254 | 313 | 127 | 270 | 191 | 45 | 3831112531345 | 23121-2312-125 |

150 | 6" | 8 | 280 | 267 | 331 | 140 | 400 | 283 | 57 | 3831112531437 | 23121-2312-150 |

200 | 8" | 8 | 343 | 292 | 361 | 172 | 600 | 424 | 88 | 3831112531529 | 23121-2312-200 |

30-150 kPa | |||||||||||

65 | 2 1/2" | 4 | 180 | 190 | 274 | 90 | 75 | 53 | 18 | 3831112531086 | 23121-2322-065 |

80 | 3" | 4 | 191 | 203 | 281 | 96 | 110 | 78 | 21 | 3831112531178 | 23121-2322-080 |

100 | 4" | 8 | 229 | 229 | 303 | 115 | 180 | 127 | 34 | 3831112531253 | 23121-2322-100 |

125 | 5" | 8 | 254 | 254 | 313 | 127 | 270 | 191 | 45 | 3831112531352 | 23121-2322-125 |

150 | 6" | 8 | 280 | 267 | 331 | 140 | 400 | 283 | 57 | 3831112531444 | 23121-2322-150 |

200 | 8" | 8 | 343 | 292 | 361 | 172 | 600 | 424 | 88 | 3831112531536 | 23121-2322-200 |

80-400 kPa | |||||||||||

65 | 2 1/2" | 4 | 180 | 190 | 274 | 90 | 75 | 53 | 18 | 3831112531093 | 23121-2332-065 |

80 | 3" | 4 | 191 | 203 | 281 | 96 | 110 | 78 | 21 | 3831112531185 | 23121-2332-080 |

100 | 4" | 8 | 229 | 229 | 303 | 115 | 180 | 127 | 34 | 3831112531260 | 23121-2332-100 |

125 | 5" | 8 | 254 | 254 | 313 | 127 | 270 | 191 | 45 | 3831112531369 | 23121-2332-125 |

150 | 6" | 8 | 280 | 267 | 331 | 140 | 400 | 283 | 57 | 3831112531451 | 23121-2332-150 |

200 | 8" | 8 | 343 | 292 | 361 | 172 | 600 | 424 | 88 | 3831112531543 | 23121-2332-200 |

Kvm = m3/h at a pressure drop of 1 bar and maximum opening corresponding to the p-band.

For working area less than Kv = 4.

Expansion vessel

For working area less than Kv = 4.

1,2 m capillary pipe (Ø6 mm), capillary pipe connection Ø6xR1/4 (separate part) + Ø6xR1/8 (mounted on valve) and capillary pipe connection with shut-off Ø6xG3/8 are included.

Factory set at 3 bar.

H | D | EAN | Article No |

266 | 90 | 3831112532052 | 23124-2542-001 |

For capillary pipe Ø6 mm with R1/4 or R1/8 connection.

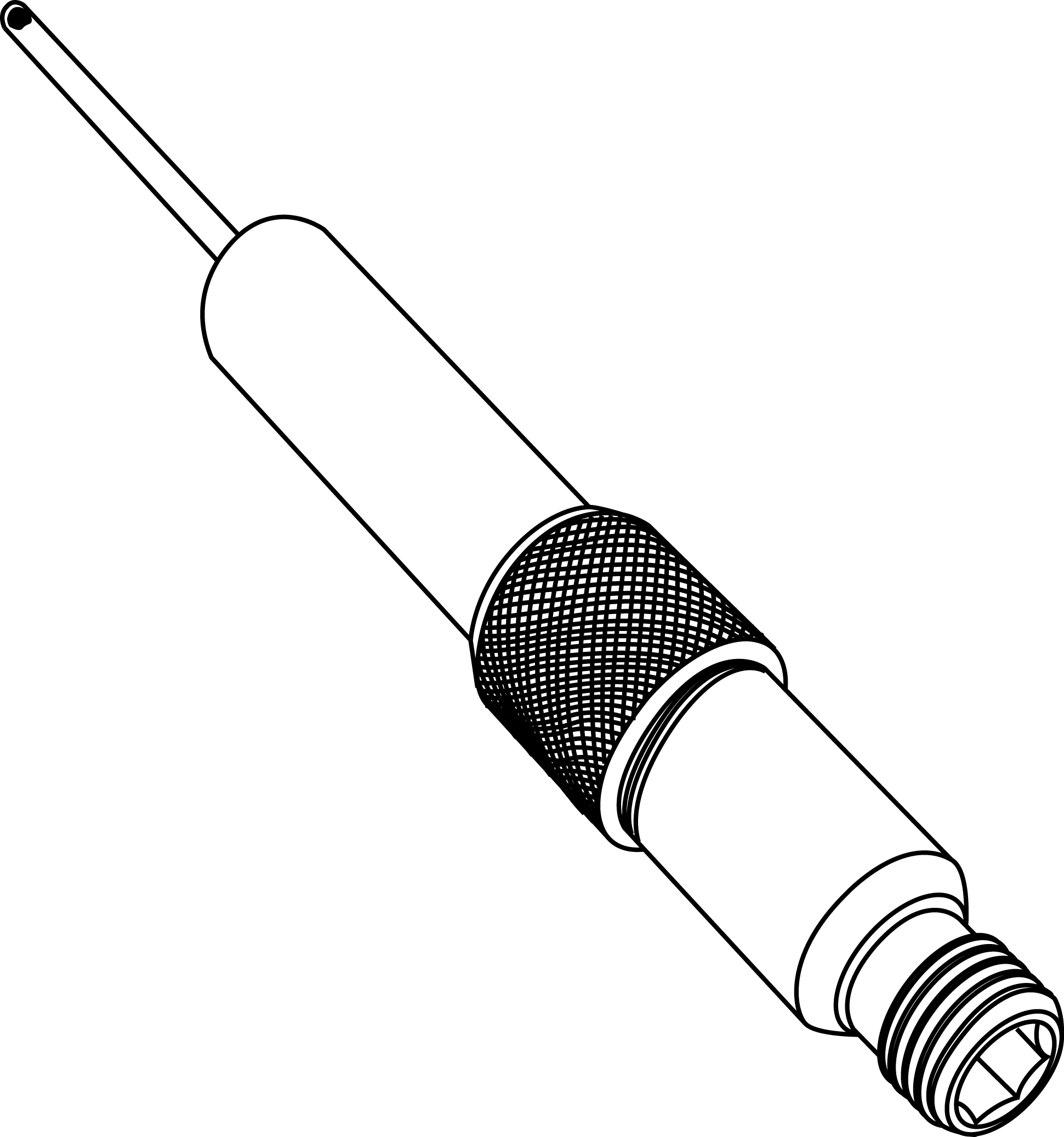

Capillary pipe connection

For capillary pipe Ø6 mm with R1/4 or R1/8 connection.

1 pc 6xR1/4 included in TA-PILOT-R as a separate part. (Ø6xR1/8 mounted on valve).

EAN | Article No | |

6xR1/4 | 3831112527355 | 52 759-201 |

6xR1/8 | 3831112533868 | 52 759-213 |

Brass/EPDM

Venting screw

Brass/EPDM

d | EAN | Article No |

M6 | 3831112527980 | 52 759-211 |

Can be installed without draining of the system.AMETAL®/Stainless steel/EPDM

Measuring point, extension 60 mm

Can be installed without draining of the system.

AMETAL®/Stainless steel/EPDM

L | EAN | Article No |

60 | 7318792812804 | 52 179-006 |

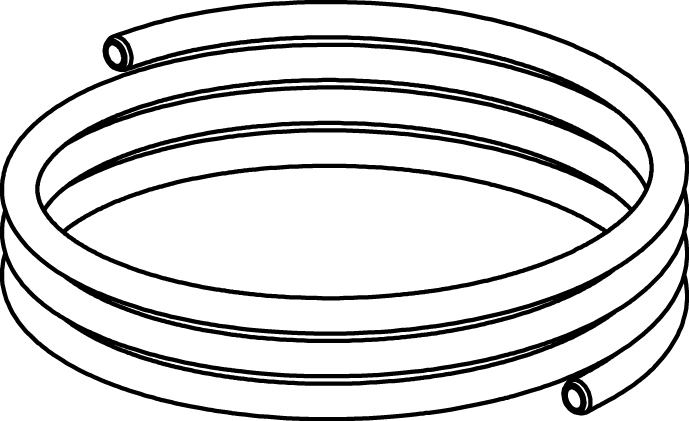

Capillary pipe

Ø6 mm

1 pc included in TA-PILOT-R.

L [m] | EAN | Article No |

1,2 | 3831112527157 | 52 759-215 |

Capillary pipe connection with shut-off

For replacement of existing measuring point on STAF/STAF-SG.

52 265-208:

1 pc G3/8 included in TA-PILOT-R.

d | D | For DN | EAN | Article No |

G1/4 | 6 | 20-50 | 7318793999504 | 52 265-209 |

G3/8 | 6 | 65-400 | 7318793999405 | 52 265-208 |

Max 120°C (intermittent 150°C)AMETAL®/EPDM

Measuring point

Max 120°C (intermittent 150°C)

AMETAL®/EPDM

d | L | EAN | Article No |

M14x1 | 44 | 7318792813207 | 52 179-014 |

M14x1 | 103 | 7318793858108 | 52 179-015 |

Suitable when insulation is used.Stainless steel/EPDM/Brass.

Venting extension

Suitable when insulation is used.

Stainless steel/EPDM/Brass.

d | D | L | EAN | Article No |

M6 | 12 | 70 | 3831112531727 | 52 759-220 |

For connection of capillary pipe while permitting simultaneous use of our balancing instrument.

Measuring point, two-way

For connection of capillary pipe while permitting simultaneous use of our balancing instrument.

For connection to existing measuring point on STAF/STAF-SG.

Can be installed during operation.

D | H | EAN | Article No |

6 | 68 | 7318793848703 | 52 179-206 |

Photos

TA-PILOT-R_DN100_w_vessel

Select a format Download

52759215

Select a format Download

TA-PILOT-R_DN100

Select a format Download

231212112100

Select a format Download

TA-PILOT-R_DN100_kat_w_path

Select a format Download

52265208

Select a format Download

52179015

Select a format Download

52179206

Select a format Download

Expansion_vessel_TA-PILOT-R

Select a format Download

231242542001

Select a format Download