Features & Benefits

Degasazione sotto vuoto ciclonica ad elevata efficienza

Efficienza significativamente più elevata rispetto alla maggioranza dei degasatori sotto vuoto presenti sul mercato.

Degasazione diretta dell’acqua di reintegro

per una protezione aggiuntiva contro la corrosione.

Facilità di messa in servizio, accesso remoto e ricerca dei guasti

Collegamenti integrati standard per il nostro server online IMI e BMS.

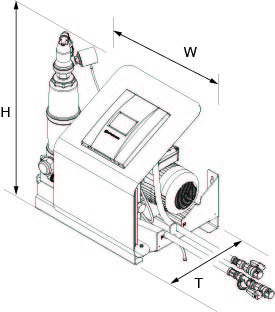

Vento Compact

Design compatto per installazione a pavimento o a parete.

Supporto a parete fonoaonoassorbente opzionale

Per Vento Compact installazioni in luoghi particolarmente sensibili al rumore strutturale.

Gamma completa

A servizio di impianti con pressione statica da 0,5 a 20,5 bar

Technical Information

Applicazioni:

Impianti di riscaldamento, raffrescamento e solari.

Per impianti conformi alle norme EN 12828, SWKI HE301-01, EN 12976, ENV 12977, EN 12952, EN 12953

Fluido:

Sistema atossico e non aggressivo.

Antigelo a base di glicole etilenico o propilenico, fino al 50%.

Pressione:

Pressione minima ammissibile, PSmin: -1 bar

Pressione massima ammissibile, PS: Vedi articoli

Temperatura:

Temperatura minima ammissibile, TSmin: 0°C

Temperatura massima ammissibile, TS: 90°C

Temperatura ambiente ammissibile max., TA: 40°C

Temperatura ambiente ammissibile min., TAmin: 0°C

Tensione elettrica:

Vento V/VF:

1 x 230 V (± 10 %) / 50 Hz

Vento VI:

Tensione di rete: 3x400V (± 10%) / 50Hz (3P+PE)

Tensione di comando: 230V (± 10%) / 50Hz (P+N+PE)

Collegamenti elettrici:

Fusibili in loco in base alla potenza richiesta e alle normative locali

4 (V/VI) o 3 (VF) uscite prive di potenziale (NA) per indicazione di allarme esterno (230 V max. 2 A)

1 ingresso/uscita RS 485

1 presa Ethernet RJ45

1 presa per Hub USB

Morsettiera in PowerCube per cablaggio diretto (Vento VI).

Grado di protezione degli involucri:

IP 54 conforme ai EN 60529

Collegamenti idraulici:

Vento V/VI

Sin1: ingresso dall’impianto G3/4"

Sout: uscita all’impianto G3/4"

Swm: ingresso per il reintegro dell’acqua G3/4"

Vento VF

Sin1: ingresso dall’impianto G1/2"

Sout: uscita all’impianto G1/2"

Swm: ingresso per il reintegro dell’acqua G3/4"

Materiali:

Componenti metallici a contatto con il mezzo: acciaio dolce, ghisa, acciaio inox, AMETAL®, ottone, bronzo per cannoni.

Trasporto e stoccaggio:

In posti asciutti e privi di gelo.

Norme di riferimento:

Costruito a norma

MD 2006/42/EC, Annex II 1.A

EMC-D. 2014/30/EU

Articolo

Vento Compact Connect

Degasatore sotto vuoto ciclonico. 1 pompa e 2 elettrovalvole, 1 unità di degasazione sotto vuoto ciclonica, attacco per reintegro automatico con elettrovalvola e misuratore di portata, e unità di controllo BrainCube Connect.

2 tubi di collegamento con valvole a sfera. Attacchi G1/2".

Modello | W | H | T | m [kg] | Pel [kW] | VNd [m3] | SPL [dB(A)] | dpu [bar] | EAN | Codice art. | |

10 bar (PS) | |||||||||||

V 2.1 FE | 520 | 575 | 350 | 32 | 0,75 | 10 | ~55* | 0,5 - 2,5 | 7640161642294 | 303030-20400 | |

T = Profondità dell’apparecchio

VNd = Volume d'acqua omologato

Pel = Potenza elettrica assorbita

dpu = Campo di pressione di lavoro

*) Con pompa in funzione

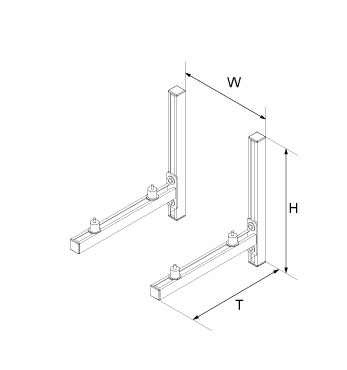

Supporto a parete WB VSF

Supporto a parete fonoaonoassorbente per Simply Vento Connect e Vento Compact Connect. Riduce al minimo ed in modo affidabile la trasmissione del suono per via strutturale dall'unità alla parete di montaggio.

Modello | W * | H | T | m [kg] | EAN | Article No |

WB VSF | 376 | 500 | 520 | 7,5 | 7640161644557 | 301032-30021 |

*) = Distanza da centro a centro per un montaggio ottimale.

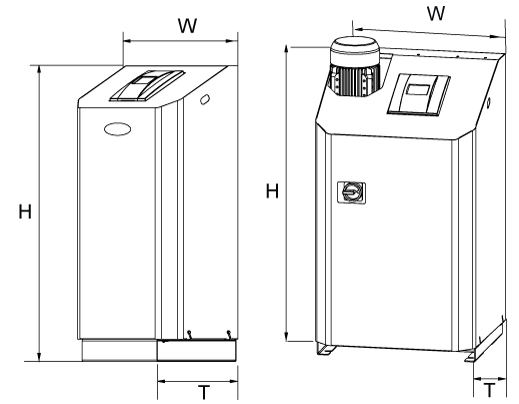

Vento V/VI .1 E Connect

Degasatore sotto vuoto ciclonico. 1 pompa, 1 elettrovalvola e 1 valvola motorizzata, 1 unità di degasazione sotto vuoto ciclonica, attacco per reintegro automatico con elettrovalvola e misuratore di portata, e unità di controllo BrainCube Connect.

Modello | W | H | T | m [kg] | Pel [kW] | VNd [m3] | SPL [dB(A)] | dpu [bar] | EAN | Codice art. | |

10 bar (PS) | |||||||||||

V 4.1 E | 500 | 920 | 530 | 40 | 0,75 | 300 | ~55* | 1-2,5 | 7640161629752 | 812 1101 | |

V 6.1 E | 500 | 920 | 530 | 42 | 1,1 | 300 | ~55* | 1,5-3,5 | 7640161629769 | 812 1102 | |

V 8.1 E | 500 | 920 | 530 | 43 | 1,4 | 300 | ~55* | 2-4,5 | 7640161629776 | 812 1103 | |

V 10.1 E | 500 | 1300 | 530 | 57 | 1,7 | 300 | ~60* | 3,5-6,5 | 7640161629783 | 812 1104 | |

13 bar (PS) | |||||||||||

V 14.1 E | 500 | 1300 | 530 | 67 | 1,7 | 300 | ~60* | 5,5-10 | 7640161629790 | 812 1105 | |

25 bar (PS) | |||||||||||

VI 19.1 E | 570 | 1086 | 601 | 78 | 2,6 | 300 | ~60* | 6,5-15,5 | 7640161636774 | 303031-60600 | |

VI 25.1 E | 570 | 1258 | 601 | 85 | 3,4 | 300 | ~60* | 10,5-20,5 | 7640161636781 | 303031-60700 | |

T = Profondità dell’apparecchio

VNd = Volume d'acqua omologato

Pel = Potenza elettrica assorbita

dpu = Campo di pressione di lavoro

*) Con pompa in funzione

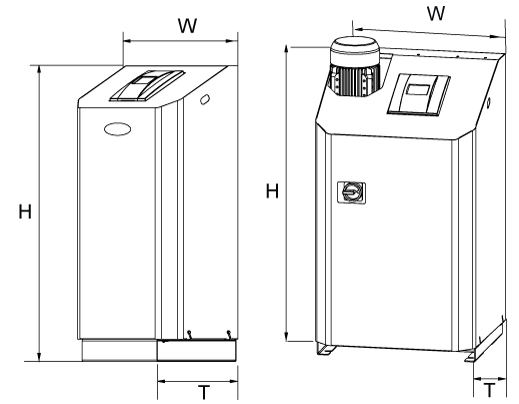

Vento V/VI .1 EC Connect

Degasatore sotto vuoto ciclonico. 1 pompa, 1 elettrovalvola e 1 valvola motorizzata, 1 unità di degasazione sotto vuoto ciclonica, attacco per reintegro automatico con elettrovalvola e misuratore di portata, e unità di controllo BrainCube Connect.

Isolamento anticondensa per installazione in impianti di raffrescamento.

Modello | W | H | T | m [kg] | Pel [kW] | VNd [m3] | SPL [dB(A)] | dpu [bar] | EAN | Codice art. | |

10 bar (PS) | |||||||||||

V 4.1 EC | 500 | 920 | 530 | 41 | 0,75 | 300 | ~55* | 1-2,5 | 7640161629806 | 812 1201 | |

V 6.1 EC | 500 | 920 | 530 | 43 | 1,1 | 300 | ~55* | 1,5-3,5 | 7640161629813 | 812 1202 | |

V 8.1 EC | 500 | 920 | 530 | 44 | 1,4 | 300 | ~55* | 2-4,5 | 7640161629820 | 812 1203 | |

V 10.1 EC | 500 | 1300 | 530 | 58 | 1,7 | 300 | ~60* | 3,5-6,5 | 7640161629837 | 812 1204 | |

13 bar (PS) | |||||||||||

V 14.1 EC | 500 | 1300 | 530 | 68 | 1,7 | 300 | ~60* | 5,5-10 | 7640161629844 | 812 1205 | |

25 bar (PS) | |||||||||||

VI 19.1 EC | 570 | 1086 | 601 | 86 | 2,6 | 300 | ~60* | 6,5-15,5 | 7640161636958 | 303031-70600 | |

VI 25.1 EC | 570 | 1258 | 601 | 94 | 3,4 | 300 | ~60* | 10,5-20,5 | 7640161636941 | 303031-70700 | |

T = Profondità dell’apparecchio

VNd = Volume d'acqua omologato

Pel = Potenza elettrica assorbita

dpu = Campo di pressione di lavoro

*) Con pompa in funzione

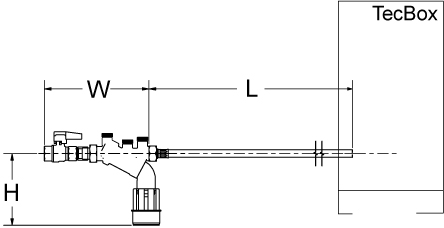

Modulo idraulico per la protezione del reintegro dell’acqua compatibile con Vento/Transfero Connect, Pleno PX/PIX, Simply Compresso C 2.1-80 SWM ed in combinazione con i moduli Pleno Refill. Consiste in una valvola d’intercettazione, valvola di ritegno, un filtro ed un disconnettore idraulico tipo BA (classe di protezione 4) secondo normativa EN 1717.Attacco (Swm): G1/2.

Pleno P BA4 R

Modulo idraulico per la protezione del reintegro dell’acqua compatibile con Vento/Transfero Connect, Pleno PX/PIX, Simply Compresso C 2.1-80 SWM ed in combinazione con i moduli Pleno Refill. Consiste in una valvola d’intercettazione, valvola di ritegno, un filtro ed un disconnettore idraulico tipo BA (classe di protezione 4) secondo normativa EN 1717.

Attacco (Swm): G1/2.

Modello | PS [bar] | W | L | H | m [kg] | qwm [l/h] | EAN | Codice art. |

BA4 R | 10 | 210 | 1300 | 135 | 1,1 | 350* 250** 50*** q(pw-pout) **** | 7640161630147 | 813 3310 |

qwm = portata di reintegro d'acqua

* valore medio massimo per la degasazione dell'acqua di reintegro con Vento V/VI e Transfero TV/TVI

** valore medio massimo per la degasazione dell'acqua di reintegro con Vento Compact

*** quando si utilizza il limitatore di portata per il funzionamento con cartucce di trattamento acqua a bassa portata

**** per combinazioni con Pleno PX/PIX fare riferimento al diagramma q(pw-pout) nella scheda tecnica del Pleno Connect

Dispositivo idraulico per il reintegro dell’acqua compatibile con Vento/Transfero Connect. Consiste di un disconnettore Pleno P BA4 R e di un modulo Pleno P AB5, classe di protezione 5 secondo EN 1717.

Pleno P AB5 R

Dispositivo idraulico per il reintegro dell’acqua compatibile con Vento/Transfero Connect. Consiste di un disconnettore Pleno P BA4 R e di un modulo Pleno P AB5, classe di protezione 5 secondo EN 1717.

Modello | PS [bar] | T | H1 | H2 | m [kg] | qwm [l/h] | EAN | Codice art. |

AB5 R | 10 | 220 | 280 | 1000 | 3,8 | 200 | 7640161630161 | 813 3330 |

qwm = portata di reintegro d'acqua

T = Profondità dell’apparecchio

Dispositivo idraulico per il reintegro dell’acqua compatibile con Vento/Transfero Connect. Consiste in un vaso intermedio di tipo AB (classe di protezione 5) secondo normativa EN 1717. Da installarsi sul retro dell’unità. Può essere utilizzato con dispositivi di addolcimento di altri produttori, che non soddisfano il requisito qwm min 1300 l/h, che possono quindi venir connessi direttamente.

Pleno P AB5

Dispositivo idraulico per il reintegro dell’acqua compatibile con Vento/Transfero Connect. Consiste in un vaso intermedio di tipo AB (classe di protezione 5) secondo normativa EN 1717. Da installarsi sul retro dell’unità. Può essere utilizzato con dispositivi di addolcimento di altri produttori, che non soddisfano il requisito qwm min 1300 l/h, che possono quindi venir connessi direttamente.

Modello | PS [bar] | T | H1 | H2 | m [kg] | qwm [l/h] | EAN | Codice art. |

AB5 | 10 | 220 | 280 | 1000 | 1,83 | 200 | 7640161630154 | 813 3320 |

qwm = portata di reintegro d'acqua

T = Profondità dell’apparecchio

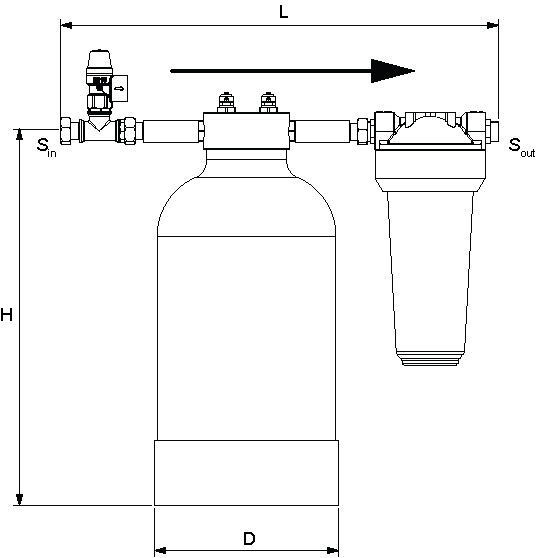

Dispositivo idraulico per addolcimento dell'acqua compatibile con i TecBox Vento/Transfero Connect. Filtro con maglia di dimensioni 25 nm per proteggere l'impianto. Cartuccia di addolcimento con resina di elevata qualità.

Pleno Refill

Dispositivo idraulico per addolcimento dell'acqua compatibile con i TecBox Vento/Transfero Connect. Filtro con maglia di dimensioni 25 nm per proteggere l'impianto. Cartuccia di addolcimento con resina di elevata qualità.

Attacco con codolo 3/4", filetto esterno da 3/4" adatto per guarnizione piatte.

Pressione Nominale: PS 8

Temp. max. di esercizio: 45°C

Temp. min. di esercizio: >4°C

Modello | Capacità l x °dH | Sin | Sout | D | H | L | m [kg] | EAN | Codice art. |

Refill 16000 | 16000 | G3/4 | G3/4 | 195 | 383 | 455 | 9,1 | 7640161630475 | 813 3210 |

Refill 36000 | 36000 | G3/4 | G3/4 | 220 | 466 | 455 | 13 | 7640161630482 | 813 3220 |

Refill 48000 | 48000 | G3/4 | G3/4 | 270 | 458 | 455 | 16,2 | 7640161630499 | 813 3230 |

→ = Direzione di flusso

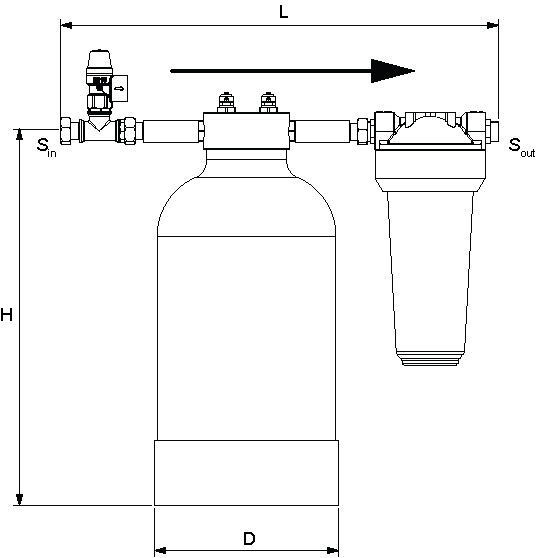

Dispositivo idraulico per desalinizzazione dell'acqua compatibile con i TecBox Vento/Transfero Connect. Filtro con maglia di dimensioni 25 nm per proteggere l'impianto. Cartuccia di addolcimento con resina di elevata qualità.

Pleno Refill Demin

Dispositivo idraulico per desalinizzazione dell'acqua compatibile con i TecBox Vento/Transfero Connect. Filtro con maglia di dimensioni 25 nm per proteggere l'impianto. Cartuccia di addolcimento con resina di elevata qualità.

Attacco con codolo 3/4", filetto esterno da 3/4" adatto per guarnizione piatte.

Pressione Nominale: PS 8

Temp. max. di esercizio: 45°C

Temp. min. di esercizio: >4°C

Modello | Capacità l x °dH | Sin | Sout | D | H | L | m [kg] | EAN | Codice art. |

Refill Demin 13500 | 13500 | G3/4 | G3/4 | 220 | 466 | 455 | 13 | 7640161630505 | 813 3260 |

Refill Demin 18000 | 18000 | G3/4 | G3/4 | 270 | 458 | 455 | 16,2 | 7640161630512 | 813 3270 |

→ = Direzione di flusso