Features & Benefits

Higher Efficiency Cyclonic vacuum degassing

Significantly higher efficiency than most other vacuum degassing systems.

Direct degassing of make-up water

For additional protection against corrosion.

Easy Commissioning, Remote Access and Trouble-shooting

Integrated standard connections to our IMI Webserver and to BMS.

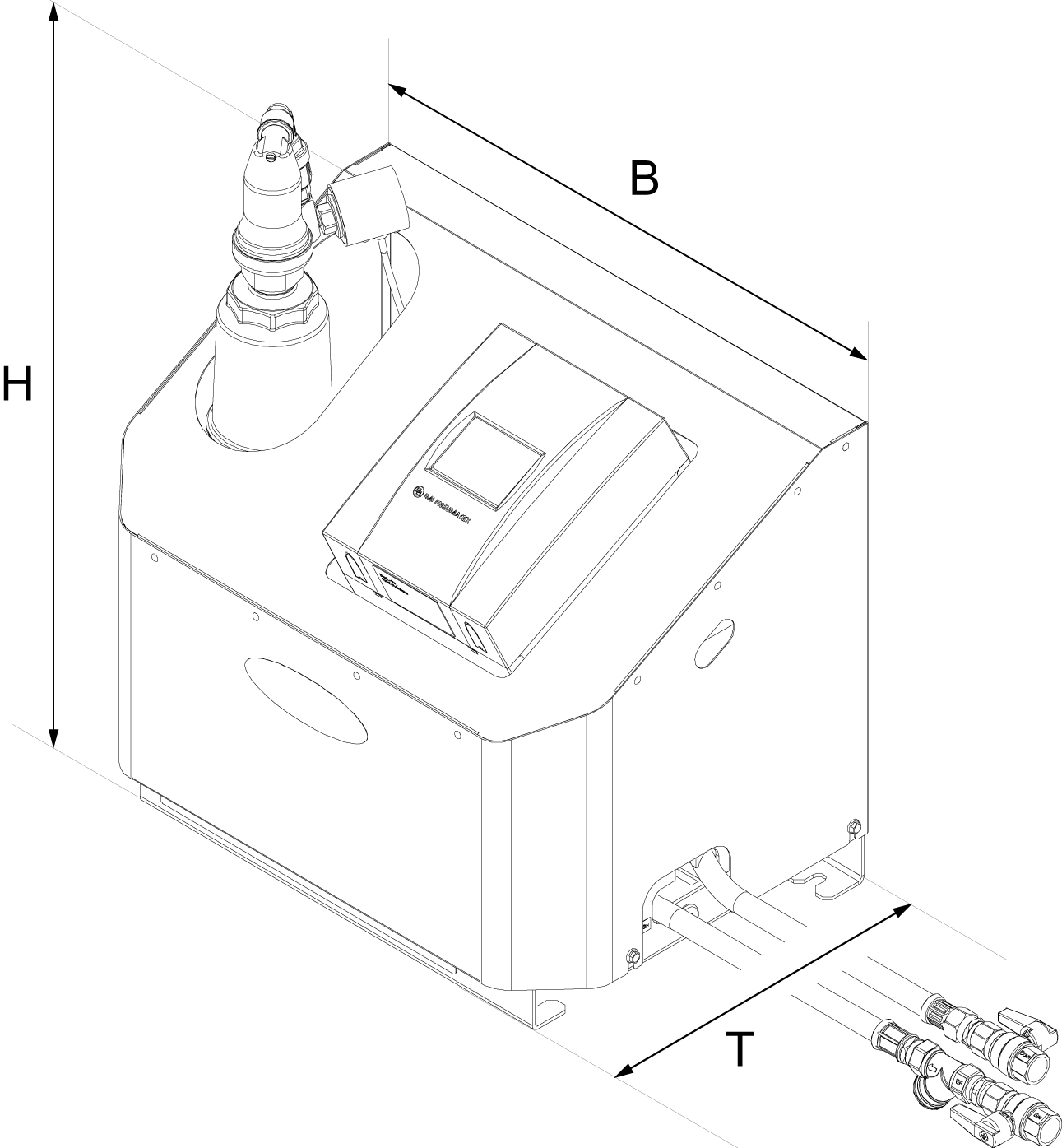

Vento Compact

Compact design for floor and wall hanging installation

Optional sound absorbing wall bracket

For Vento Compact in installations particularly sensitive to structure-borne sound.

Full range

Serving installations from 0,5 - 20,5 bar

Technical Information

Applications:

Heating, solar and chilled water systems. For systems according to EN 12828, SWKI HE301-01, EN 12976, ENV 12977, EN 12952, EN 12953

Media:

Non-aggressive and non-toxic system media.

Ethylene or propylene glycol-based antifreeze up to 50%.

Pressure:

Min. admissible pressure, PSmin: -1 bar

Max. admissible pressure, PS: see Articles

Temperature:

Min. admissible temperature, TSmin: 0°C

Max. admissible temperature, TS: 90°C

Max. admissible ambient temperature, TA: 40°C

Min. admissible ambient temperature, TAmin: 0°C

Supply voltage:

Vento V/VF:

1 x 230 V (± 10 %) / 50 Hz

Vento VI:

Main voltage: 3x400V (± 10%) / 50Hz (3P+PE)

Control voltage: 230V (± 10%) / 50Hz (P+N+PE)

Electrical connections:

Onsite fuses according to power demand and local norms

4 (V/VI) or 3 (VF) potential-free outputs (NO) for external alarm indication (230V max. 2A)

1 RS 485 In/Output

1 Ethernet RJ45 plug socket

1 USB Hub plug socket

Terminal strip in PowerCube for direct wiring (Vento VI).

Enclosure class:

IP54 according to EN 60529

Mechanical connections:

Vento V/VI:

Sin1: inlet from the system G3/4"

Sout: outlet to the system G3/4"

Swm: inlet water make-up G3/4"

Vento VF:

Sin1: inlet from the system G1/2"

Sout: outlet to the system G1/2"

Swm: inlet water make-up G3/4"

Material:

Metal components with medium contact: carbon steel, cast iron, stainless steel, AMETAL®, brass, gunmetal.

Transportation and storage:

In frostless, dry places.

Standard:

Constructed according to

LV-D. 2014/35/EU

EMC-D. 2014/30/EU

Articles

Vento Compact Connect

Cyclonic vacuum degassing unit. 1 pump and 2 solenoid valves, cyclonic vacuum degassing unit, connection for water make-up with solenoid valve and water meter and BrainCube Connect control.

2 connection hoses with ball valves. Connections G1/2”.

Type | B | H | T | m [kg] | Pel [kW] | VNd [m3] | SPL [dB(A)] | dpu [bar] | EAN | Article No | |

10 bar (PS) | |||||||||||

V 2.1 FE | 520 | 575 | 350 | 32 | 0,75 | 10 | ~55* | 0,5 - 2,5 | 7640161642294 | 303030-20400 | |

T = Depth of the device

VNd = Water capacity for which a device is rated

Pel = Electric load

dpu = Working pressure range

*) Pump operation

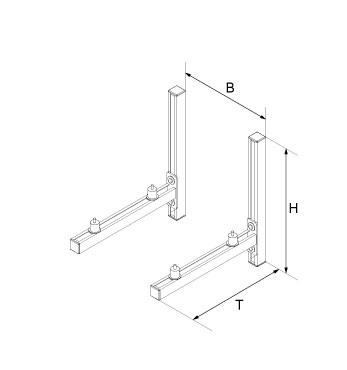

Wall bracket WB VSF

Sound-absorbing wall bracket for Simply Vento Connect and Vento Compact Connect.

Reliably reduces the transmission of structure-borne sound from the unit to the mounting wall to a minimum.

Type | B | H | T | m [kg] | EAN | |

WB VSF | 376 | 500 | 520 | 7,5 | 7640161644557 | 301032-30021 |

B = Centre-to-centre distance for optimum mounting

Vento V/VI .1 E Connect

Cyclonic vacuum degassing unit. 1 pump, 1 solenoid valve and 1 motor driven valve, 1 cyclonic vacuum degassing unit, connection for water make-up with solenoid valve and water meter, and BrainCube Connect control.

Type | B | H | T | m [kg] | Pel [kW] | VNd [m3] | SPL [dB(A)] | dpu [bar] | EAN | Article No | |

10 bar (PS) | |||||||||||

V 4.1 E | 500 | 920 | 530 | 40 | 0,75 | 300 | ~55* | 1-2,5 | 7640161629752 | 812 1101 | |

V 6.1 E | 500 | 920 | 530 | 42 | 1,1 | 300 | ~55* | 1,5-3,5 | 7640161629769 | 812 1102 | |

V 8.1 E | 500 | 920 | 530 | 43 | 1,4 | 300 | ~55* | 2-4,5 | 7640161629776 | 812 1103 | |

V 10.1 E | 500 | 1300 | 530 | 57 | 1,7 | 300 | ~60* | 3,5-6,5 | 7640161629783 | 812 1104 | |

13 bar (PS) | |||||||||||

V 14.1 E | 500 | 1300 | 530 | 67 | 1,7 | 300 | ~60* | 5,5-10 | 7640161629790 | 812 1105 | |

16 bar (PS) | |||||||||||

VI 19.1 E | 570 | 1086 | 601 | 78 | 2,6 | 300 | ~60* | 6,5-15,5 | 7640161636774 | 303031-60600 | |

25 bar (PS) | |||||||||||

VI 25.1 E | 570 | 1258 | 601 | 85 | 3,4 | 300 | ~60* | 10,5-20,5 | 7640161636781 | 303031-60700 | |

T = Depth of the device

VNd = Water capacity for which a device is rated

Pel = Electric load

dpu = Working pressure range

*) Pump operation

Vento V/VI .1 EC Connect

Cyclonic vacuum degassing unit. 1 pump, 1 solenoid valve and 1 motor driven valve, 1 cyclonic vacuum degassing unit, connection for water make-up with solenoid valve and water meter, and BrainCube Connect control.

Cooling insulation with condensation water protection.

Type | B | H | T | m [kg] | Pel [kW] | VNd [m3] | SPL [dB(A)] | dpu [bar] | EAN | Article No | |

10 bar (PS) | |||||||||||

V 4.1 EC | 500 | 920 | 530 | 41 | 0,75 | 300 | ~55* | 1-2,5 | 7640161629806 | 812 1201 | |

V 6.1 EC | 500 | 920 | 530 | 43 | 1,1 | 300 | ~55* | 1,5-3,5 | 7640161629813 | 812 1202 | |

V 8.1 EC | 500 | 920 | 530 | 44 | 1,4 | 300 | ~55* | 2-4,5 | 7640161629820 | 812 1203 | |

V 10.1 EC | 500 | 1300 | 530 | 58 | 1,7 | 300 | ~60* | 3,5-6,5 | 7640161629837 | 812 1204 | |

13 bar (PS) | |||||||||||

V 14.1 EC | 500 | 1300 | 530 | 68 | 1,7 | 300 | ~60* | 5,5-10 | 7640161629844 | 812 1205 | |

16 bar (PS) | |||||||||||

VI 19.1 EC | 570 | 1086 | 601 | 86 | 2,6 | 300 | ~60* | 6,5-15,5 | 7640161636958 | 303031-70600 | |

25 bar (PS) | |||||||||||

VI 25.1 EC | 570 | 1258 | 601 | 94 | 3,4 | 300 | ~60* | 10,5-20,5 | 7640161636941 | 303031-70700 | |

T = Depth of the device

VNd = Water capacity for which a device is rated

Pel = Electric load

dpu = Working pressure range

*) Pump operation

Hydraulic unit for water make-up operation with Vento/Transfero Connect, Pleno PX/PIX, Simply Compresso C 2.1-80 SWM, and in combination with Pleno Refill modules. Features a shut off valve, check valve, filter and a type BA backflow preventer (protection class 4) according to EN 1717.Connection (Swm): G1/2

Pleno P BA4 R

Hydraulic unit for water make-up operation with Vento/Transfero Connect, Pleno PX/PIX, Simply Compresso C 2.1-80 SWM, and in combination with Pleno Refill modules. Features a shut off valve, check valve, filter and a type BA backflow preventer (protection class 4) according to EN 1717.

Connection (Swm): G1/2

Type | PS [bar] | B | L | H | m [kg] | qwm [l/h] | EAN | Article No |

BA4 R | 10 | 210 | 1300 | 135 | 1,1 | 350* 250** 50*** q(pw-pout) **** | 7640161630147 | 813 3310 |

qwm = make-up water flow

* maximum average value for make-up water degassing with Vento V/VI and Transfero TV/TVI

** maximum average value for make-up water degassing with Vento Compact

*** when using flow limiter for operation with low flow water treatment cartridges

**** for combination with Pleno PX/PIX see q(pw-pout) diagram in Pleno Connect datasheet

Hydraulic unit for water make up operation with Vento/Transfero Connect. Consists of Pleno P BA4 R back flow preventer and Pleno P AB5 modules, with protection class 5 according to EN 1717.

Pleno P AB5 R

Hydraulic unit for water make up operation with Vento/Transfero Connect. Consists of Pleno P BA4 R back flow preventer and Pleno P AB5 modules, with protection class 5 according to EN 1717.

Type | PS [bar] | T | H1 | H2 | m [kg] | qwm [l/h] | EAN | Article No |

AB5 R | 10 | 220 | 280 | 1000 | 3,8 | 200 | 7640161630161 | 813 3330 |

qwm = make-up water flow

T = Depth of the device

Hydraulic unit for water make up operation with Vento/Transfero Connect. Consists of a breaktank type AB (protection class 5) according EN 1717. For installation on the back of each unit. Can be used for 3rd party softening modules which do not fulfil the requirement of qwm min 1300 l/h and therefore cannot be directly connected.

Pleno P AB5

Hydraulic unit for water make up operation with Vento/Transfero Connect. Consists of a breaktank type AB (protection class 5) according EN 1717. For installation on the back of each unit. Can be used for 3rd party softening modules which do not fulfil the requirement of qwm min 1300 l/h and therefore cannot be directly connected.

Type | PS [bar] | T | H1 | H2 | m [kg] | qwm [l/h] | EAN | Article No |

AB5 | 10 | 220 | 280 | 1000 | 1,83 | 200 | 7640161630154 | 813 3320 |

qwm = make-up water flow

T = Depth of the device

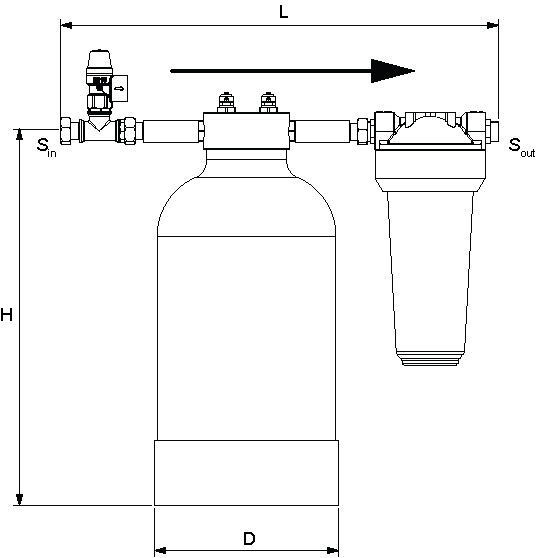

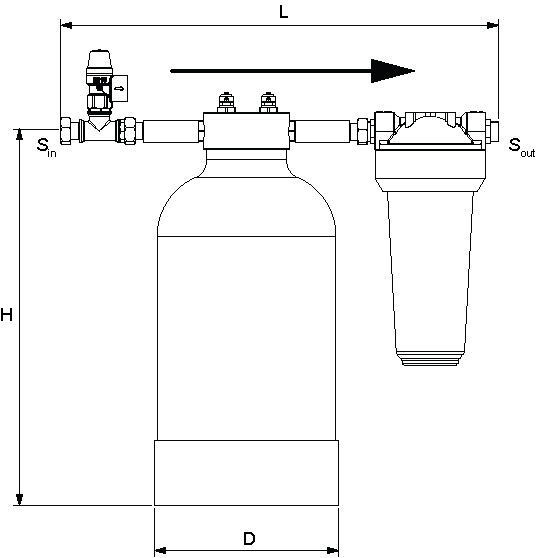

Hydraulic unit for water softening together with Vento/Transfero Connect TecBoxes. Filter with 25 µm mesh size to protect the hydronic system. Softening bottle filled with high grade resin.

Pleno Refill

Hydraulic unit for water softening together with Vento/Transfero Connect TecBoxes. Filter with 25 µm mesh size to protect the hydronic system. Softening bottle filled with high grade resin.

3/4" swivelling nut, 3/4" external thread suitable for flat gasket.

Nominal pressure: PS 8

Max. working temperature: 45°C

Min. working temperature: > 4°C

Type | Capacity l x °dH | Sin | Sout | D | H | L | m [kg] | EAN | Article No |

Refill 16000 | 16000 | G3/4 | G3/4 | 195 | 383 | 455 | 9,1 | 7640161630475 | 813 3210 |

Refill 36000 | 36000 | G3/4 | G3/4 | 220 | 466 | 455 | 13 | 7640161630482 | 813 3220 |

Refill 48000 | 48000 | G3/4 | G3/4 | 270 | 458 | 455 | 16,2 | 7640161630499 | 813 3230 |

→ = Flow direction

Hydraulic unit for water demineralisation together with Vento/Transfero Connect TecBoxes. Filter with 25 µm mesh size to protect the hydronic system. Desalination bottle filled with high grade resin.

Pleno Refill Demin

Hydraulic unit for water demineralisation together with Vento/Transfero Connect TecBoxes. Filter with 25 µm mesh size to protect the hydronic system. Desalination bottle filled with high grade resin.

3/4" swivelling nut, 3/4" external thread suitable for flat gasket.

Nominal pressure: PS 8

Max. working temperature: 45°C

Min. working temperature: > 4°C

Type | Capacity l x °dH | Sin | Sout | D | H | L | m [kg] | EAN | Article No |

Refill Demin 13500 | 13500 | G3/4 | G3/4 | 220 | 466 | 455 | 13 | 7640161630505 | 813 3260 |

Refill Demin 18000 | 18000 | G3/4 | G3/4 | 270 | 458 | 455 | 16,2 | 7640161630512 | 813 3270 |

→ = Flow direction