Features & Benefits

Precise temperature control

Provide uniquely shaped EQM characteristic for best modulating control.

Precise control

Uniquely shaped EQM characteristic provides an up to 6 times larger operating stroke than linear valves.

Quick hydronic balancing

Automatic flow limitation when actuator is fully open protects entire system against overflows.

Easy troubleshooting

Flow and differential pressure measuring helps to reduce pump consumption and provides all necessary data for system diagnostics.

Technical Information

Application:

Heating and cooling systems.

Functions:

Control EQM: DN 15 low flow, DN 10-200 normal flow

Control LIN: DN 65-200 high flow

Pre-setting (max. flow)

Differential pressure control

Measuring (ΔH, t, q)

Isolation (for use during system maintenance – see "Leakage rate")

Dimensions:

DN 10-200

Pressure class:

DN 10-50: PN 16

DN 65-200: Class 150

Differential pressure (ΔpV):

Max. differential pressure (ΔpVmax):

DN 10-32: 600 kPa = 6 bar

DN 10-25: 400 kPa = 4 bar*

DN 40-50: 600 kPa = 6 bar

DN 65-200: 800 kPa = 8 bar

Min. differential pressure (ΔpVmin):

DN 10-20: 15 kPa = 0.15 bar

DN 25-32: 23 kPa = 0.23 bar

DN 40-200: 30 kPa = 0.30 bar

DN 65-80 HF: 45 kPa = 0.45 bar

DN 100-125 HF: 55 kPa = 0.55 bar

DN 150-200 HF: 60 kPa = 0.60 bar

(Valid for maximum setting, fully open. Other settings will require lower differential pressure, check with the software HySelect.)

ΔpVmax = The maximum allowed pressure drop over the valve to fulfill all stated performances.

ΔpVmin = The minimum recommended pressure drop over the valve, for proper differential pressure control.

*) With Δp insert in PPS.

HF = High flow

Flow range:

The flow (qmax) can be set within the range:

DN 10: 17 - 120 l/h

DN 15 LF: 38 - 230 l/h

DN 15: 92 - 480 l/h

DN 20: 200 - 975 l/h

DN 25: 340 - 1750 l/h

DN 32: 720 - 3600 l/h

DN 40: 1000 - 6500 l/h

DN 50: 2150 - 11200 l/h

DN 65: 4150 - 24100 l/h

DN 65 HF: 7460 - 36500 l/h

DN 80: 5850 - 37300 l/h

DN 80 HF: 9520 - 49000 l/h

DN 100: 11700 - 51700 l/h

DN 100 HF: 18000 - 75900 l/h

DN 125: 15000 - 77300 l/h

DN 125 HF: 23300 - 127000 l/h

DN 150: 26100 - 126000 l/h

DN 150 HF: 38800 - 190000 l/h

DN 200: 35000 - 209000 l/h

DN 200 HF: 73200 - 329000 l/h

qmax = l/h at each setting and fully open valve plug.

LF = Low flow

HF = High flow

Temperature:

DN 10-32:

Max. working temperature: 120°C

Min. working temperature: -20°C

DN 10-25 with Δp insert in PPS, DN 40-50:

Max. working temperature: 90°C

Min. working temperature: -10°C

DN 65-200:

Max. working temperature: 120°C

Min. working temperature: -10°C

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Lift:

DN 10-20: 4 mm

DN 25-32: 6,5 mm

DN 40-50: 15 mm

DN 65-125: 20 mm

DN 150: 30 mm

DN 200: 32,5 mm

Rangeability:

DN 10 - 15 LF: >50

DN 15 - 32: >75

DN 40 - 80: >125

DN 100 - 150: >150

DN 100 - 150 HF: >125

DN 200: >125

DN 200 HF: >125

Leakage rate:

Leakage flow ≤ 0.01% of max. qmax (max. setting) and correct flow direction. (Class IV according to EN 60534-4).

Characteristics:

Independent shaped EQM.

DN 65-200 HF: Linear.

Material:

DN 10-32:

Valve body: AMETAL®

Valve insert: AMETAL® and PPS

Valve plug: Brass CW724R (CuZn21Si3P)

Spindle: Stainless steel

Spindle seal: EPDM O-ring

Δp insert: PPS and AMETAL® or PPS

Membrane: EPDM

Springs: Stainless steel

O-rings: EPDM

DN 40-50:

Valve body: AMETAL®

Valve insert: AMETAL®

Valve plug: AMETAL® and PTFE

Spindle: Stainless steel

Spindle seal: EPDM O-ring

Δp insert: PPS

Membrane: EPDM

Springs: Stainless steel

O-rings: EPDM

DN 65-200:

Valve body: Ductile iron EN-GJS-400-15

Valve insert: Ductile iron EN-GJS-400-15 and brass

Valve plug: Stainless steel and EPDM O-ring

Valve seat: Aluminium bronze

Spindle: Stainless steel

Spindle seal: EPDM

Δp insert: Ductile iron EN-GJS-400-15, stainless steel and brass.

Membrane: Reinforced EPDM, DN 200 EPDM

Springs: Stainless steel

O-rings: EPDM

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Surface treatment:

DN 10-50: Non treated

DN 65-200: Electrophoretic painting

Connection:

DN 10-50: External thread according to ISO 228. Connections (accessories) with internal and external thread NPT according to ANSI/ASME B1.20.1-1983, or for soldering according to ASME/ANSI B16.18.

DN 65-200: Flanges according to ASME 7 ANSI B16.42 Class 150.

Connection to actuator:

DN 10-32: M30x1.5, push

DN 40-50: M30x1.5, push/pull

DN 65-200: 2xM8, push/pull

Actuators:

DN 10-20:

TA-Slider 160, EMO TM, TA-TRI.

DN 25-32:

TA-Slider 160, TA-TRI, TA-MC50-C*.

DN 40-50:

TA-Slider 500, TA-Slider 750*.

DN 65-125:

TA-Slider 750.

DN 100-125 HF:

TA-Slider 750 ΔpV ≤ 4 bar, TA-Slider 1600 ΔpV ≤ 8 bar.

DN 150-200, DN 150-200 HF:

TA-Slider 1600.

TA-Slider 160, 500, 750 and 1600 also available with fail-safe function.

*) Adapter to be ordered separately, see "Adapters for actuators".

For more details on actuators, see separate technical leaflets.

Certification and directives:

DN 65-200: CE, EAC, UKCA

Articles

External threads according to ISO 228.

DN 10-32 HP – Temperature -20 – +120°C, ΔpV max. 600 kPa

External threads according to ISO 228.

NPT threads - see "Connections".

DN | d | L | H1 | H2 | W | qmax [l/h] | Kg | EAN | Article No |

10 | G1/2 | 74 | 55 | 55 | 54 | 120 | 0,59 | 5902276821431 | 52 164-410 |

15 LF | G3/4 | 74 | 55 | 55 | 54 | 230 | 0,60 | 5902276821448 | 52 164-414 |

15 | G3/4 | 74 | 55 | 55 | 54 | 480 | 0,60 | 7318794033405 | 52 164-415 |

20 | G1 | 85 | 64 | 55 | 64 | 975 | 0,75 | 7318794033504 | 52 164-420 |

25 | G1 1/4 | 93 | 64 | 67 | 64 | 1750 | 0,90 | 7318794033603 | 52 164-425 |

32 | G1 1/2 | 117 | 78 | 70 | 78 | 3600 | 1,5 | 7318794027305 | 52 164-332 |

LF = Low flow

→ = Flow direction

*) Connection to actuator.

External threads according to ISO 228.

DN 10-25 – Temperature -10 – +90°C, ΔpV max. 400 kPa

External threads according to ISO 228.

NPT threads - see "Connections".

DN | d | L | H1 | H2 | W | qmax [l/h] | Kg | EAN | Article No |

10 | G1/2 | 74 | 55 | 55 | 54 | 120 | 0,53 | 7318794040304 | 52 164-310 |

15 LF | G3/4 | 74 | 55 | 55 | 54 | 230 | 0,54 | 5902276821424 | 52 164-314 |

15 | G3/4 | 74 | 55 | 55 | 54 | 480 | 0,54 | 7318794027008 | 52 164-315 |

20 | G1 | 85 | 64 | 55 | 64 | 975 | 0,69 | 7318794027107 | 52 164-320 |

25 | G1 1/4 | 93 | 64 | 67 | 64 | 1750 | 0,79 | 7318794027206 | 52 164-325 |

LF = Low flow

→ = Flow direction

*) Connection to actuator.

External threads according to ISO 228.

DN 40-50 HP – Temperature -10 – +90°C, ΔpV max. 600 kPa

External threads according to ISO 228.

NPT threads - see "Connections".

DN | d | L | H | W | qmax [l/h] | Kg | EAN | Article No |

40 | G2 | 187 | 132 | 88 | 6500 | 3,5 | 5902276821769 | 52 164-440 |

50 | G2 1/2 | 196 | 135 | 88 | 11200 | 3,9 | 5902276821776 | 52 164-450 |

→ = Flow direction

*) Connection to actuator.

DN 65-200 – Temperature -10 – +120°C, ΔpV max. 800 kPa

Flanges according to ASME 7 ANSI B16.42 Class 150.

Class 150

DN | Number of bolt holes | ØD | L | H | qmax [m3/h] | Kg | EAN | Article No |

65 | 4 | 180 | 290 | 249 | 24,1 | 18 | 3831112533295 | 322021-11003 |

65 HF | 4 | 180 | 290 | 249 | 36,5 | 18 | 5902276810237 | 322021-11010 |

80 | 4 | 190 | 310 | 260 | 37,3 | 22 | 3831112533332 | 322021-11103 |

80 HF | 4 | 190 | 310 | 260 | 49,0 | 22 | 5902276810275 | 322021-11111 |

100 | 8 | 230 | 350 | 280 | 51,7 | 33 | 3831112535541 | 322021-11202 |

100 HF | 8 | 230 | 350 | 280 | 75,9 | 33 | 3831112535589 | 322021-11205 |

125 | 8 | 255 | 400 | 287 | 77,3 | 45 | 3831112535626 | 322021-11302 |

125 HF | 8 | 255 | 400 | 287 | 127 | 45 | 3831112535664 | 322021-11305 |

150 | 8 | 280 | 480 | 357 | 126 | 75 | 3831112535725 | 322021-11402 |

150 HF | 8 | 280 | 480 | 357 | 190 | 75 | 3831112535763 | 322021-11405 |

200 | 8 | 343 | 600 | 391 | 209 | 136 | 5902276819858 | 322021-11502 |

200 HF | 8 | 343 | 600 | 391 | 329 | 136 | 5902276819865 | 322021-11505 |

HF = High flow

→ = Flow direction

*) Connection to actuator.

Threads according to ANSI/ASME B1.20.1-1983.Swivelling nut

With internal thread NPT

Threads according to ANSI/ASME B1.20.1-1983.

Swivelling nut

Brass/AMETAL®

For DN | D | D1 | L* | EAN | Article No |

10 | G1/2 | 3/8 NPT | 21 | 7318794017801 | 52 163-210 |

15 | G3/4 | 1/2 NPT | 25 | 7318794017900 | 52 163-215 |

20 | G1 | 1/2 NPT | 18 | 7318794018303 | 52 163-320 |

20 | G1 | 3/4 NPT | 23 | 7318794018006 | 52 163-220 |

25 | G1 1/4 | 3/4 NPT | 27 | 7318794018402 | 52 163-325 |

25 | G1 1/4 | 1 NPT | 27 | 7318794018105 | 52 163-225 |

32 | G1 1/2 | 1 NPT | 27 | 7318794018501 | 52 163-332 |

32 | G1 1/2 | 1 1/4 NPT | 31 | 7318794018204 | 52 163-232 |

40 | G2 | 1 NPT | 30 | 7318794033108 | 52 163-340 |

40 | G2 | 1 1/2 NPT | 32 | 7318794032903 | 52 163-240 |

50 | G2 1/2 | 1 1/2 NPT | 32 | 7318794033207 | 52 163-350 |

50 | G2 1/2 | 2 NPT | 32 | 7318794033009 | 52 163-250 |

*) Fitting length (from the gasket surface to the end of the connection).

Other type of connections (ISO), see international version of TA-Modulator.

Threads according to ANSI/ASME B1.20.1-1983.Swivelling nut

With external thread NPT

Threads according to ANSI/ASME B1.20.1-1983.

Swivelling nut

Brass

For DN | D | D1 | L* | EAN | Article No |

10 | - | - | - | - | - |

15 | G3/4 | 1/2 NPT | 29 | 4024052928415 | 2400-02.350 |

20 | G1 | 3/4 NPT | 32,5 | 4024052928514 | 2400-03.350 |

25 | G1 1/4 | 1 NPT | 35 | 4024052928613 | 2400-04.350 |

32 | - | - | - | - | - |

*) Fitting length (from the gasket surface to the end of the connection).

Other type of connections (ISO), see international version of TA-Modulator.

According to ASME/ANSI B16.18Swivelling nut

Soldering connection

According to ASME/ANSI B16.18

Swivelling nut

Brass/gunmetal CC491K (EN 1982)

For DN | D | Pipe Ø [in] | ~ [mm] | L* | EAN | Article No |

10 | G1/2 | 0.504 | 12.8 | 13 | 7318794022805 | 52 009-710 |

15 | G3/4 | 0.629 | 16 | 16 | 7318794022904 | 52 009-715 |

20 | G1 | 0.879 | 22 | 22 | 7318794023000 | 52 009-720 |

25 | G1 1/4 | 1.130 | 29 | 26 | 7318794023109 | 52 009-725 |

32 | G1 1/2 | 1.380 | 35 | 28 | 7318794023208 | 52 009-732 |

40 | G2 | 1.630 | 41 | 31 | 7318794033900 | 52 009-740 |

50 | G2 1/2 | 2.130 | 54 | 38 | 7318794034006 | 52 009-750 |

*) Fitting length (from the gasket surface to the end of the connection).

Other type of connections (ISO), see international version of TA-Modulator.

Adapters to other combinations of valve and recommended actuator are NOT needed.

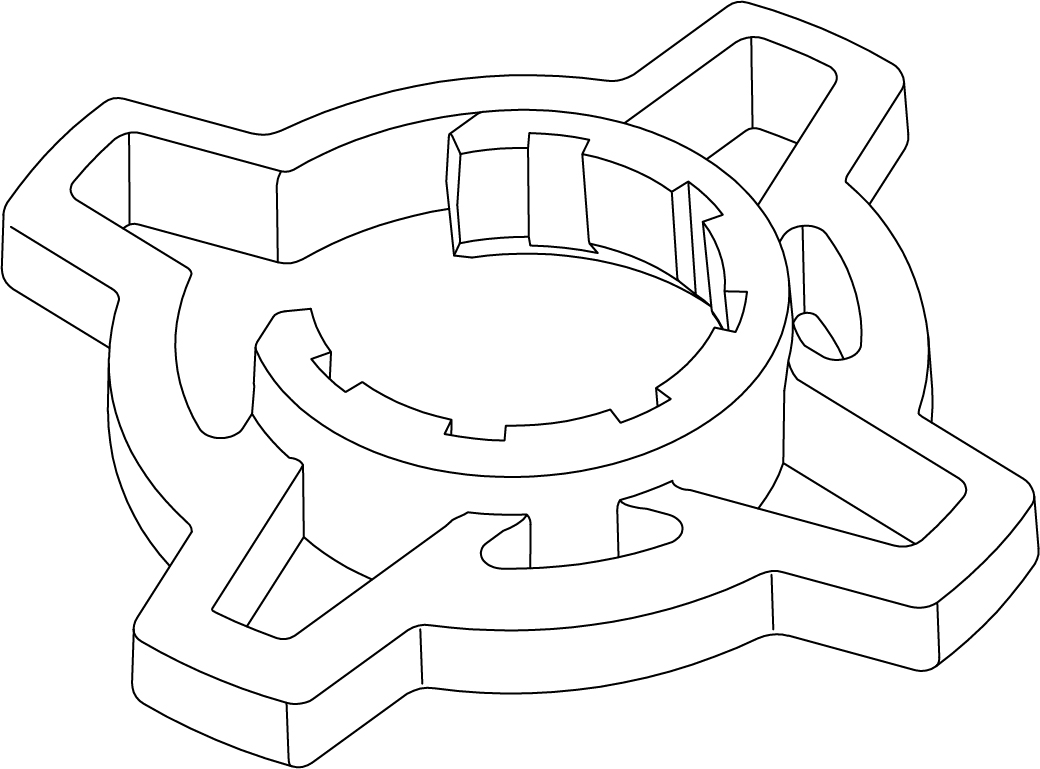

Adapters

Adapters to other combinations of valve and recommended actuator are NOT needed.

For actuator | For DN | EAN | Article No |

TA-MC50-C | 25-32 | 3831112533851 | 322042-10700 |

TA-Slider 750 | 40-50 | 5902276819308 | 322042-80800 |

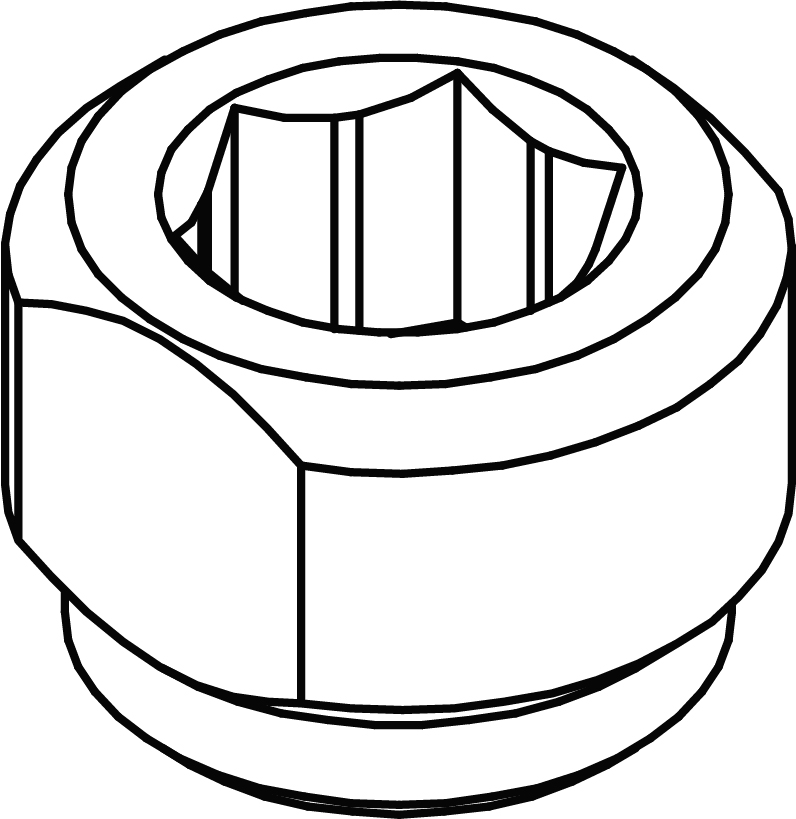

Spare part.

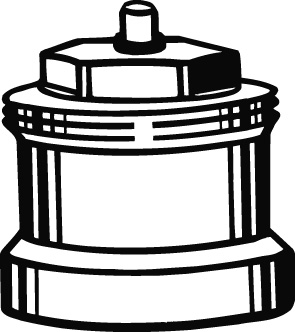

Venting plug

Spare part.

AMETAL®

For DN | EAN | Article No |

40-50 | 7318794033801 | 52 164-302 |

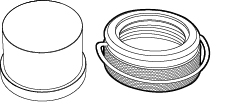

For TA-COMPACT-P/-DP, TA-Modulator (DN 10-20), TBV-C/-CM.

Protection cap

For TA-COMPACT-P/-DP, TA-Modulator (DN 10-20), TBV-C/-CM.

Colour | EAN | Article No |

Red | 7318793961105 | 52 143-100 |

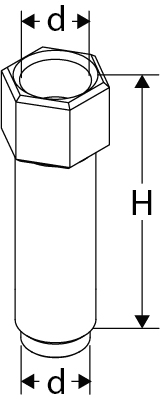

Suitable when insulation is used.

Venting extension

Suitable when insulation is used.

AMETAL®

For DN | D | d | H | EAN | Article No |

40-50 | M10x1 | M10x1 | 32 | 7318794033702 | 52 164-301 |

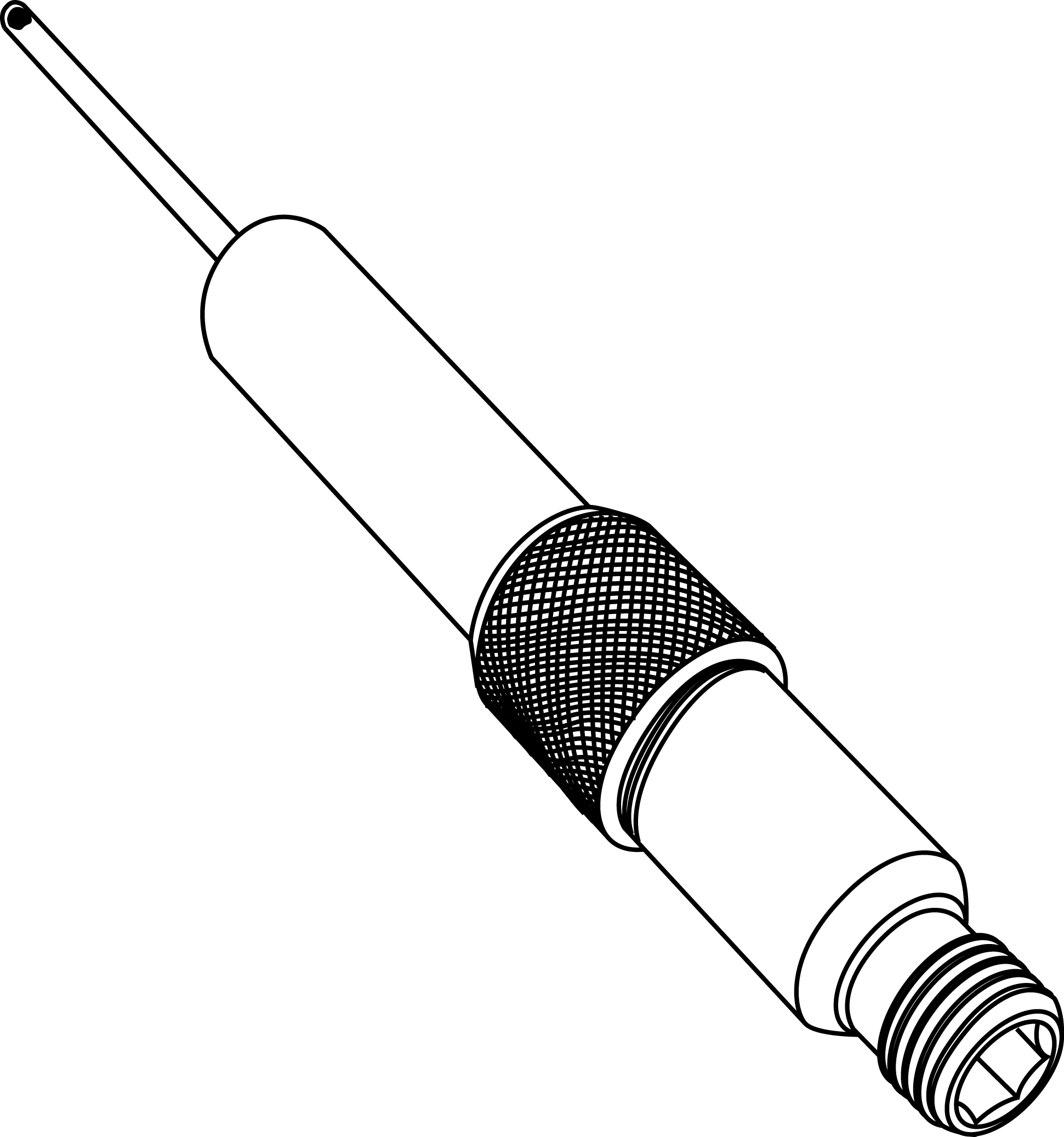

Can be installed without draining of the system.AMETAL®/Stainless steel/EPDM

Measuring point, extension 60 mm

Can be installed without draining of the system.

AMETAL®/Stainless steel/EPDM

For all dimensions.

L | EAN | Article No |

60 | 7318792812804 | 52 179-006 |

Set containing plastic cover and locking ring for valves with connection M30x1.5 to thermostatic head/actuator. Prevents manipulation of setting.

Tamper proof cover

Set containing plastic cover and locking ring for valves with connection M30x1.5 to thermostatic head/actuator.

Prevents manipulation of setting.

Suitable for DN 10-32.

EAN | Article No |

7318794030206 | 52 164-100 |

Recommended together with the insulation to minimize the risk of condensation at the valve-actuator interface.M30x1,5.

Spindle extension for DN 10-20

Recommended together with the insulation to minimize the risk of condensation at the valve-actuator interface.

M30x1,5.

Type | L | EAN | Article No |

Plastic, black | 30 | 4024052165018 | 2002-30.700 |

For heating/comfort cooling.Material: EPP.Fire class: DN 10-32: E (EN 13501-1), B2 (DIN 4102).DN 40-50: F (EN 13501-1), B3 (DIN 4102).

Insulation

For heating/comfort cooling.

Material: EPP.

Fire class:

DN 10-32: E (EN 13501-1), B2 (DIN 4102).

DN 40-50: F (EN 13501-1), B3 (DIN 4102).

For DN | L | H | H1 | H2 | W | EAN | Article No |

10-15 | 100 | - | 61 | 71 | 84 | 7318794027404 | 52 164-901 |

20 | 118 | - | 67 | 79 | 90 | 7318794027503 | 52 164-902 |

25 | 127 | - | 71 | 84 | 104 | 7318794027602 | 52 164-903 |

32 | 154 | - | 85 | 99 | 124 | 7318794027701 | 52 164-904 |

40 | 277 | 105 | - | - | 131 | 7318794030800 | 52 164-905 |

50 | 277 | 105 | - | - | 131 | 7318794030909 | 52 164-906 |

For better grip when presetting.For TA-COMPACT-P/-DP and TA-Modulator (DN 10-32).

Grip for setting wheel, optional

For better grip when presetting.

For TA-COMPACT-P/-DP and TA-Modulator (DN 10-32).

Colour | EAN | Article No |

Orange | 7318794040502 | 52 164-950 |

Photos

52164425

Select a format Download

52164302

Select a format Download

52164420

Select a format Download

TA-Modulator_DN15_metal_persp

Select a format Download

32204210700

Select a format Download

TA-MODULATOR_persp_kat_w_path

Select a format Download

TA-Modulator_DN80

Select a format Download

52164901-904

Select a format Download

32204280800

Select a format Download

52164332

Select a format Download

TA-Modulator_DN50_persp

Select a format Download

240002350

Select a format Download

TA-Modulator_DN50

Select a format Download

52164325

Select a format Download

52164315

Select a format Download

TA-Modulator_DN80_persp

Select a format Download

TA-Modulator_DN15_metal

Select a format Download

52164301

Select a format Download

32202111103

Select a format Download

32202111003

Select a format Download

52164320

Select a format Download

52163215

Select a format Download

52164350

Select a format Download

52143100

Select a format Download

52164100

Select a format Download

52164415

Select a format Download

52164950

Select a format Download

52164901-904_persp

Select a format Download