Features & Benefits

Precise hydronic balancing

Smoothly adjustable setting of max. flow prevents over flow through terminal unit.

Installations without limits

Slim and compact shape simplifies installation, one side access to all functions simplifies operation.

Full control of the system

Exact flow measuring and unique diagnostic functions for ultimate energy savings and highly reliable system.

High reliability

AMETAL® and stainless steel guarantees high corrosion resistance and reduces the risk of leakage.

Technical Information

Application:

Heating and cooling systems.

Functions:

Control

Pre-setting (max. flow)

Differential pressure control

Measuring (ΔH, T, q)

Isolation (for use during system maintenance – see also Leakage rate)

Dimensions:

DN 10-32

Pressure class:

PN 16

Differential pressure (ΔpV):

Max. differential pressure (ΔpVmax): 400 kPa = 4 bar

Min. differential pressure (ΔpVmin):

DN 10-20: 15 kPa = 0,15 bar

DN 25-32: 23 kPa = 0,23 bar

(Valid for position 10, fully open. Other positions will require lower differential pressure, check with the software HySelect.)

ΔpVmax = The maximum allowed pressure drop over the valve to fulfill all stated performances.

ΔpVmin = The minimum recommended pressure drop over the valve, for proper differential pressure control.

Flow range:

The flow (qmax) can be set within the range:

DN 10: 21,5 - 120 l/h

DN 15 LF: 44 - 245 l/h

DN 15: 88 - 470 l/h

DN 20: 210 - 1150 l/h

DN 25: 370 - 2150 l/h

DN 32: 800 - 3700 l/h

qmax = l/h at each setting and fully open valve plug.

LF = Low flow

Temperature:

Max. working temperature: 90°C

Min. working temperature: -10°C

Media:

Water or neutral fluids, water-glycol mixtures (0-57%).

Lift:

4 mm

Leakage rate:

Leakage flow ≤ 0,01% of max. qmax (setting 10) and correct flow direction. (Class IV according to EN 60534-4).

Characteristics:

Linear, best suited for on/off control.

Material:

Valve body: AMETAL®

Valve insert: AMETAL®

Valve plug: Brass CW724R (CuZn21Si3P)

Spindle: Stainless steel

Spindle seal: EPDM O-ring

Δp insert: PPS

Membrane: EPDM and HNBR

Springs: Stainless steel

O-rings: EPDM

AMETAL® is the dezincification resistant alloy of IMI Hydronic Engineering.

Marking:

TA, IMI, PN 16, DN and flow direction arrow.

Grey handwheel: TA-COMPACT-P and DN. For low flow version also LF.

Connection:

External threads according to ISO 228.

Connection to actuator:

M30x1.5

Actuators:

See separate technical documentation on EMO T and TA-TRI.

Articles

Threads according to ISO 228.

Male thread

Threads according to ISO 228.

DN | d | L | H1 | H2 | W | qmax [l/h] | Kg | EAN | Article No |

10 | G1/2 | 74 | 55 | 55 | 54 | 120 | 0,53 | 7318794013308 | 52 164-010 |

15 LF | G3/4 | 74 | 55 | 55 | 54 | 245 | 0,54 | 7318794025202 | 52 164-115 |

15 | G3/4 | 74 | 55 | 55 | 54 | 470 | 0,54 | 7318794013407 | 52 164-015 |

20 | G1 | 85 | 64 | 55 | 64 | 1150 | 0,69 | 7318794013506 | 52 164-020 |

25 | G1 1/4 | 93 | 64 | 61 | 64 | 2150 | 0,79 | 7318794013605 | 52 164-025 |

32 | G1 1/2 | 112 | 78 | 61 | 78 | 3700 | 1,5 | 7318794013704 | 52 164-032 |

LF = Low flow

*) Connection to actuator.

→ = Flow direction

For connection with press coupling. Swivelling nut.

Connection with smooth end

For connection with press coupling.

Swivelling nut.

Valve DN | D | Pipe Ø | L* | EAN | Article No |

10 | G1/2 | 12 | 35 | 7318793810502 | 52 009-312 |

15 | G3/4 | 15 | 39 | 7318793810601 | 52 009-315 |

20 | G1 | 18 | 44 | 7318793810700 | 52 009-318 |

20 | G1 | 22 | 48 | 7318793810809 | 52 009-322 |

25 | G1 1/4 | 28 | 53 | 7318793810908 | 52 009-328 |

32 | G1 1/2 | 35 | 59 | 7318793811004 | 52 009-335 |

*) Fitting length (from the gasket surface to the end of the connection).

Compression connection

Support bushes shall be used, for more information see catalogue leaflet FPL.

Should not be used with PEX pipes.

Chrome plated

Valve DN | D | Pipe Ø | L** | EAN | Article No |

10 | G1/2 | 8 | 16 | 7318793620002 | 53 319-208 |

10 | G1/2 | 10 | 17 | 7318793620101 | 53 319-210 |

10 | G1/2 | 12 | 17 | 7318793620200 | 53 319-212 |

10 | G1/2 | 15 | 20 | 7318793620309 | 53 319-215 |

10 | G1/2 | 16 | 25 | 7318793620408 | 53 319-216 |

15 | G3/4 | 15 | 27 | 7318793705006 | 53 319-615 |

15 | G3/4 | 18 | 27 | 7318793705105 | 53 319-618 |

15 | G3/4 | 22 | 27 | 7318793705204 | 53 319-622 |

**) Over all length L refers to unassembled coupling.

Threads according to ISO 7-1. Swivelling nut.

With External thread

Threads according to ISO 7-1.

Swivelling nut.

Valve DN | D | D1 | L* | EAN | Article No |

10 | - | - | - | - | - |

15 | G3/4 | R1/2 | 29 | 4024052516612 | 0601-02.350 |

20 | G1 | R3/4 | 32,5 | 4024052516810 | 0601-03.350 |

25 | G1 1/4 | R1 | 35 | 4024052517015 | 0601-04.350 |

32 | G1 1/2 | R1 1/4 | 38,5 | 4024052517213 | 0601-05.350 |

*) Fitting length (from the gasket surface to the end of the connection).

Threads according to ISO 228.

With internal thread

Threads according to ISO 228.

Thread length according to ISO 7-1.

Swivelling nut.

Valve DN | D | D1 | L* | EAN | Article No |

10 | G1/2 | G3/8 | 21 | 7318794016804 | 52 163-010 |

15 | G3/4 | G1/2 | 21 | 7318794016903 | 52 163-015 |

20 | G1 | G3/4 | 23 | 7318794017009 | 52 163-020 |

25 | G1 1/4 | G1 | 23 | 7318794017108 | 52 163-025 |

32 | G1 1/2 | G1 1/4 | 31 | 7318794017207 | 52 163-032 |

*) Fitting length (from the gasket surface to the end of the connection).

Swivelling nut.

Soldering connection

Swivelling nut.

Valve DN | D | Pipe Ø | L* | EAN | Article No |

10 | G1/2 | 10 | 10 | 7318792749100 | 52 009-510 |

10 | G1/2 | 12 | 11 | 7318792749209 | 52 009-512 |

15 | G3/4 | 15 | 13 | 7318792749308 | 52 009-515 |

15 | G3/4 | 16 | 13 | 7318792749407 | 52 009-516 |

20 | G1 | 18 | 15 | 7318792749506 | 52 009-518 |

20 | G1 | 22 | 18 | 7318792749605 | 52 009-522 |

25 | G1 1/4 | 28 | 21 | 7318792749704 | 52 009-528 |

32 | G1 1/2 | 35 | 26 | 7318792749803 | 52 009-535 |

*) Fitting length (from the gasket surface to the end of the connection).

Swivelling nut.

Welding connection

Swivelling nut.

Valve DN | D | Pipe DN | L* | EAN | Article No |

10 | G1/2 | 10 | 30 | 7318792748400 | 52 009-010 |

15 | G3/4 | 15 | 36 | 7318792748509 | 52 009-015 |

20 | G1 | 20 | 40 | 7318792748608 | 52 009-020 |

25 | G1 1/4 | 25 | 40 | 7318792748707 | 52 009-025 |

32 | G1 1/2 | 32 | 40 | 7318792748806 | 52 009-032 |

*) Fitting length (from the gasket surface to the end of the connection).

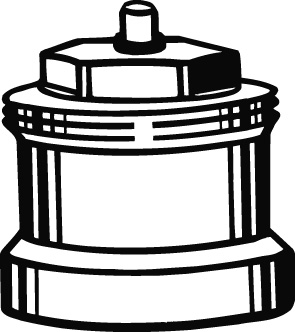

Set containing plastic cover and locking ring for valves with connection M30x1.5 to thermostatic head/actuator. Prevents manipulation of setting.

Tamper proof cover

Set containing plastic cover and locking ring for valves with connection M30x1.5 to thermostatic head/actuator.

Prevents manipulation of setting.

EAN | Article No |

7318794030206 | 52 164-100 |

For heating/comfort cooling.Material: EPP.Fire class: E (EN 13501-1), B2 (DIN 4102).

Insulation

For heating/comfort cooling.

Material: EPP.

Fire class: E (EN 13501-1), B2 (DIN 4102).

Valve DN | L | H1 | H2 | D | EAN | Article No |

10-15 | 100 | 61 | 71 | 84 | 7318794027404 | 52 164-901 |

20 | 118 | 67 | 79 | 90 | 7318794027503 | 52 164-902 |

25 | 127 | 71 | 84 | 104 | 7318794027602 | 52 164-903 |

32 | 154 | 85 | 99 | 124 | 7318794027701 | 52 164-904 |

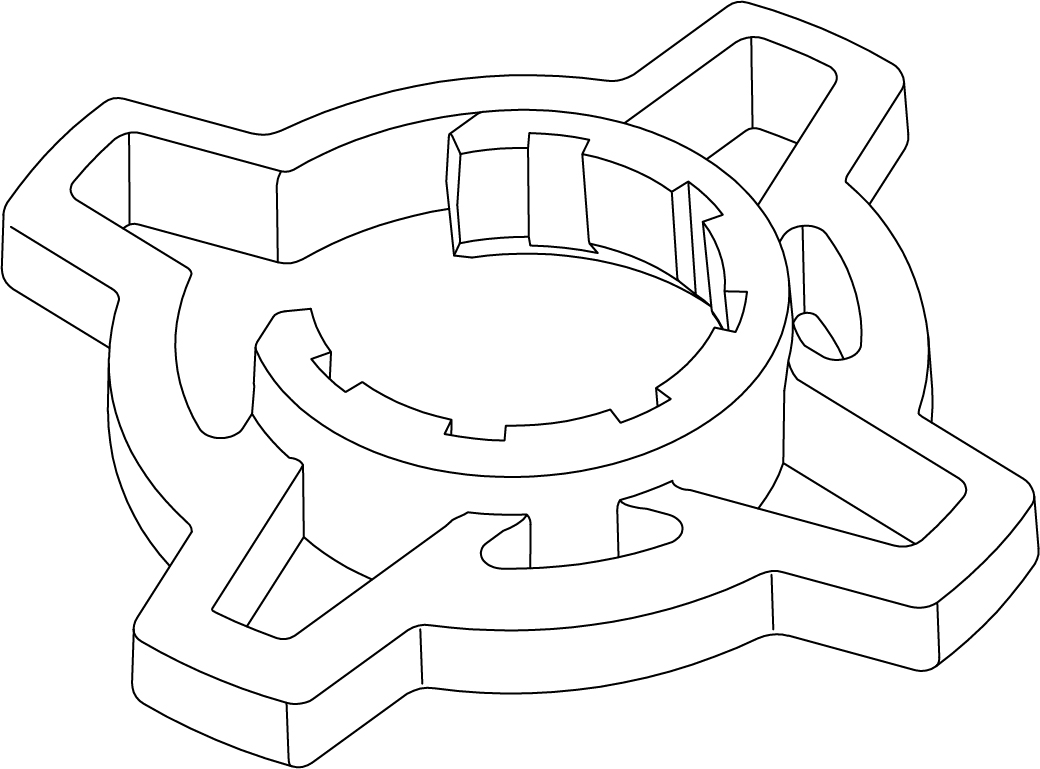

For better grip when presetting.For TA-COMPACT-P/-DP and TA-Modulator (DN 10-32).

Grip for setting wheel, optional

For better grip when presetting.

For TA-COMPACT-P/-DP and TA-Modulator (DN 10-32).

Colour | EAN | Article No |

Orange | 7318794040502 | 52 164-950 |

Recommended together with the insulation to minimize the risk of condensation at the valve-actuator interface.M30x1,5.

Spindle extension

Recommended together with the insulation to minimize the risk of condensation at the valve-actuator interface.

M30x1,5.

Type | L | EAN | Article No |

Plastic, black | 30 | 4024052165018 | 2002-30.700 |

For TA-COMPACT-P/-DP, TA-Modulator (DN 10-20), TBV-C/-CM.

Protection cap

For TA-COMPACT-P/-DP, TA-Modulator (DN 10-20), TBV-C/-CM.

Colour | EAN | Article No |

Red | 7318793961105 | 52 143-100 |

Photos

52164020

Select a format Download

TA-COMPACT-P_persp_kat

Select a format Download

52143100

Select a format Download

52164901-904_persp

Select a format Download

52164032

Select a format Download

52164115

Select a format Download

520093xx

Select a format Download

52009515

Select a format Download

220120700

Select a format Download

52164025

Select a format Download

52163015

Select a format Download

53319xxx

Select a format Download

52164100

Select a format Download

52164010

Select a format Download

52164015

Select a format Download

TA-COMPACT-P_persp_kat_w_path

Select a format Download

060102350

Select a format Download

TA-COMPACT-P

Select a format Download

520090xx

Select a format Download

52164901-904

Select a format Download