Features & Benefits

BrainCube control

Self-optimising with memory function.

Easy commissioning, remote access and remote support during troubleshooting Built-in interfaces for communication with the IMI web server and ModBus TCP and RTU for building control applications.

Pressurization

2 pumps, 2 spill connections each with 2 in series connected spill valves. Switching is time and load dependent.

PowerCube switch cabinet with halogen-free wiring

main switch with emergency stop function; 2 motor circuit breakers; Automatic soft start and soft stop for each pump.

Fillsafe water make-up monitoring

With the possibility to control water make-up through a Pleno PX.

Technical Information

Applications:

Heating, solar and chilled water systems.

For systems to EN 12828 and optional >110 °C to EN 12952, EN 12953 with additional pressure limiters Paz PMIN and water level limiter ComCube DML Connect, solar systems according to EN 12976, ENV 12977 with on-site overtemperature protection in the event of power failure.

Media:

According to VDI 2035 for non-aggressive and non-toxic system media.

Addition of antifreeze agent up to 50%.

Pressure:

Min. admissible pressure, PSmin: 0 bar

Max. admissible pressure, PS: see Articles

Temperature:

Max. admissible temperature, TS: 90°C

Min. admissible temperature, TSmin: 0°C

Max. admissible ambient temperature, TA: 40°C

Min. admissible ambient temperature, TAmin: 5°C

Accuracy:

Precision pressure maintenance ±0,2 bar.

Supply voltage:

Main current: 3x 400V / 50Hz (3P + PE)

Control voltage: 230V / 50Hz (P + N + PE)

Electrical connections:

Onsite fuses according to power demand and local norms.

4 potential free outputs ((individual parameterizable) for external message display (230V max. 2A),

2 potential-free outputs for status messages,

Motor circuit breakers of pump P1 and P2,

1 potential-free output for controlling an external water make-up device,

3 Grinding terminals for e.B. for optional pressure-, level-, temperature limiter.

1 RS 485 In/Output,

1 Ethernet RJ45 plug socket,

Terminal strip in PowerCube for direct wiring of the above-mentioned connectors,

1 USB Hub plug socket,

Software upgrade and LOG File Download.

Fire protection:

Complete electrical cabling in halogen-free version according to EN 50575 and EN 13501-6. Classification Cca s1-d1-a1 for external cables. Classification Dca s2-d2-a2 for single wires within the PowerCube control cabinet.

Enclosure class:

IP 54

Material:

In essence: steel, brass and bronze

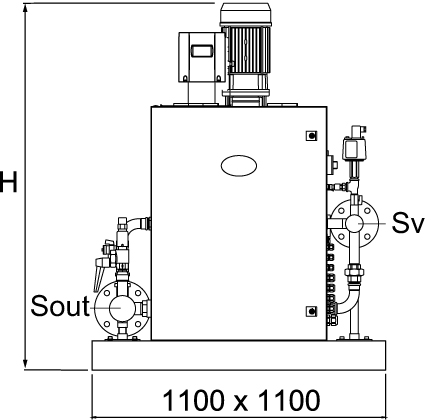

Connections:

Water make-up (Swm): Rp3/4

Connection vessel (Sv): 80/6 DN/PN

Standard:

Constructed according to

MD 2006/42/EC, Annex II 1.A

EMC-D. 2014/30/EU

Applications:

Only together with Control unit TecBox.

See Applications under Technical description - Control unit TecBox.

Transfero TGIH:

With additional electronic measuring foot LT and connection possibility of a ComCube DML for individual content measurement, content display and alarm circuit for Min/Max water level. Recommended for applications according to EN 12952 and EN 12953.

Media:

According to VDI 2035 for non-aggressive and non-toxic system media.

Addition of antifreeze agent up to 50%.

Pressure:

Min. admissible pressure, PSmin: 0 bar

Max. admissible pressure, PS: 2 bar

Temperature:

Max. admissible temperature, TS: 120 °C

Min. admissible temperature, TSmin: -10 °C

Max. admissible bag temperature, TB: 70 °C

Min. admissible bag temperature, TBmin: 5 °C

Material:

Steel, welded. Color beryllium.

Standard:

Constructed according to PED 2014/68/EU.

Warranty:

5-year warranty for the vessel.

5-year warranty for the airproof butyl bag.

Articles

Connection vessel (Sv): DN 80 / PN 6Connection water make-up (SWM): Rp 3/4

Transfero TI Connect

Connection vessel (Sv): DN 80 / PN 6

Connection water make-up (SWM): Rp 3/4

Type* | PS [bar] | H | m [kg] | Sout [DN/PN] | Pel [kW] | SPL [dB(A)] | EAN | Article No |

TI 90.2 PC1 | 16 | 1200 | 135 | 50/40 | 3,0 | <70 | 7640161643017 | 301030-80912 |

TI 120.2 PC1 | 16 | 1200 | 145 | 50/40 | 3,8 | <70 | 7640161643024 | 301030-80913 |

TI 150.2 PC1 | 16 | 1200 | 170 | 50/40 | 5,4 | <70 | 7640161643031 | 301030-80914 |

TI 190.2 PC1 | 25 | 1200 | 195 | 50/40 | 5,4 | <70 | 7640161643038 | 301030-80915 |

TI 230.2 PC1 | 25 | 1300 | 215 | 50/40 | 7,2 | <70 | 7640161643055 | 301030-80916 |

TI 61.2 PC1 | 10 | 1200 | 135 | 80/16 | 3,0 | <70 | 7640161643062 | 301030-81111 |

TI 91.2 PC1 | 10 | 1200 | 150 | 80/16 | 4,2 | <70 | 7640161643079 | 301030-81112 |

TI 111.2 PC1 | 16 | 1200 | 175 | 80/16 | 5,4 | <70 | 7640161643086 | 301030-81113 |

TI 161.2 PC1 | 16 | 1300 | 190 | 80/16 | 7,2 | <70 | 7640161643093 | 301030-81114 |

TI 231.2 PC1 | 25 | 1600 | 250 | 80/40 | 12,4 | <70 | 7640161643116 | 301030-81116 |

TI 62.2 PC1 | 10 | 1200 | 185 | 80/16 | 5,4 | <70 | 7640161643123 | 301030-81117 |

TI 102.2 PC1 | 16 | 1200 | 205 | 80/16 | 7,2 | <70 | 7640161643130 | 301030-81118 |

TI 132.2 PC1 | 16 | 1200 | 215 | 80/16 | 9,4 | <70 | 7640161643147 | 301030-81119 |

TI 182.2 PC1 | 25 | 1400 | 280 | 80/40 | 12,4 | <70 | 7640161643154 | 301030-81120 |

*) Constructions ≥ TI ..3.2 and special installations upon request.

Accessories for control modules: Communication module.

Additional equipment: Pressure limiter Paz PMIN and water level indicator ComCube DML.

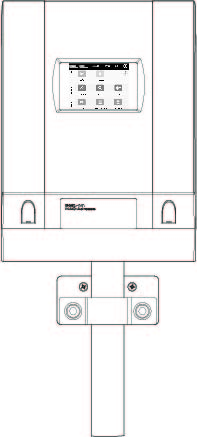

Master-Slave.

Display of the content of the connected expansion vessel. 4 potential-free, individually parametric digital outputs (NO). Each digital output is individually electronically invertible (NC). 3.5" TFT color touchscreen with lighting.Integrated standard connections (Ethernet, RS 485) to the IMI web server and the design control technology (Modbus).

ComCube DML Connect

Display of the content of the connected expansion vessel. 4 potential-free, individually parametric digital outputs (NO). Each digital output is individually electronically invertible (NC).

3.5" TFT color touchscreen with lighting.

Integrated standard connections (Ethernet, RS 485) to the IMI web server and the design control technology (Modbus).

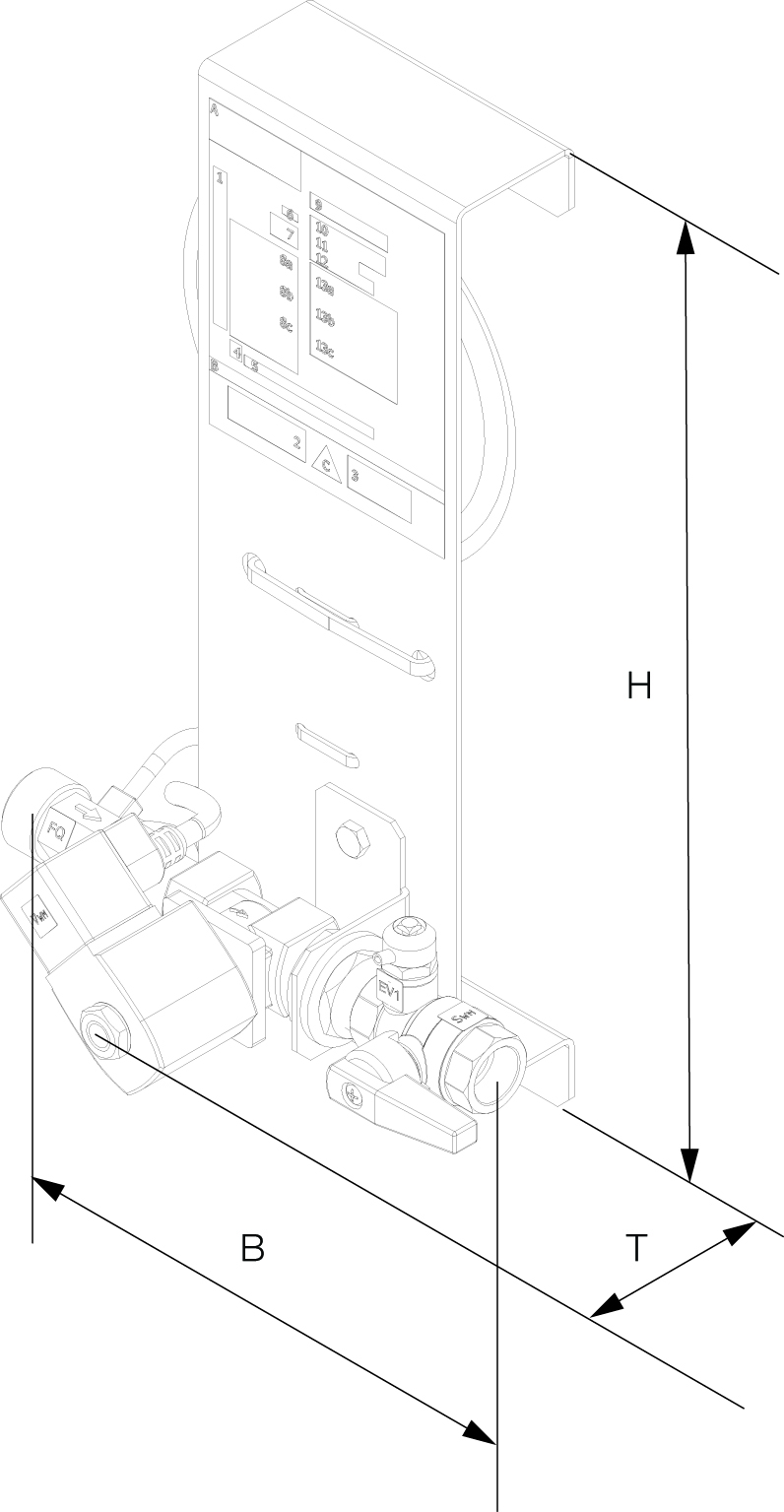

Type | B | H | T | m [kg] | Pel [kW] | EAN | Article No |

DML Connect | 180 | 220 | 140 | 1,0 | 0,1 | 7640161643168 | 301032-30018 |

T = Depth of the device

Communicator. Factory assembly in Transfero TI.2 galvanically isolated analoge outputs 4-20 mA for connection to BMS, isolation voltage 2.5 kVAC. Completely wired to mounting rail in the PowerCube control cabinet.

ComCube DCA TI

Communicator. Factory assembly in Transfero TI.

2 galvanically isolated analoge outputs 4-20 mA for connection to BMS, isolation voltage 2.5 kVAC. Completely wired to mounting rail in the PowerCube control cabinet.

Type | B | H | T | m [kg] | Pel [kW] | EAN | Article No |

DCA TI | 17,5 | 120 | 146 | 0,2 | 0,1 | 7640148638746 | 814 1015 |

T = Depth of the device

Primary vessel. 1 electr. measuring foot for content measurement, 1 electr. measuring foot for additional water level indication and min/max alarms.

Transfero TGI...H

Primary vessel. 1 electr. measuring foot for content measurement, 1 electr. measuring foot for additional water level indication and min/max alarms.

Type* | VN [l] | D | H | H*** | m [kg] | S | Sw | EAN | Article No | ||

2 bar (PS) | |||||||||||

TGI 1000H | 1000 | 850 | 2199 | 2210 | 285 | G1 1/2 | G3/4 | 7640148632102 | 713 3200 | ||

TGI 1500H | 1500 | 1016 | 2351 | 2381 | 365 | G1 1/2 | G3/4 | 7640148632119 | 713 3201 | ||

TGI 2000H | 2000 | 1016 | 2848 | 2876 | 645 | G1 1/2 | G3/4 | 7640148632126 | 713 3206 | ||

TGI 3000H | 3000 | 1300 | 2951 | 3016 | 805 | G1 1/2 | G3/4 | 7640148632133 | 713 3203 | ||

TGI 4000H | 4000 | 1300 | 3592 | 3633 | 915 | G1 1/2 | G3/4 | 7640148632140 | 713 3204 | ||

TGI 5000H | 5000 | 1300 | 4216 | 4275 | 1015 | G1 1/2 | G3/4 | 7640148632157 | 713 3205 | ||

VN = Nominal volume

*) Special vessel upon request.

**) Tolerance 0 /-100.

***) Max. height when vessel is tilted. Tolerance 0 /-100.

Additional equipment: Pressure limiter Paz PMIN and water level limiter DML Connect.

Secondary vessel.

Transfero TGI...E

Secondary vessel.

Type* | VN [l] | D | H | H*** | m [kg] | S | Sw | EAN | Article No | ||

2 bar (PS) | |||||||||||

TGI 1000E | 1000 | 850 | 2199 | 2210 | 280 | G1 1/2 | G3/4 | 7640148632041 | 713 3300 | ||

TGI 1500E | 1500 | 1016 | 2351 | 2381 | 360 | G1 1/2 | G3/4 | 7640148632058 | 713 3301 | ||

TGI 2000E | 2000 | 1016 | 2848 | 2876 | 640 | G1 1/2 | G3/4 | 7640148632065 | 713 3306 | ||

TGI 3000E | 3000 | 1300 | 2951 | 3016 | 800 | G1 1/2 | G3/4 | 7640148632072 | 713 3303 | ||

TGI 4000E | 4000 | 1300 | 3592 | 3633 | 910 | G1 1/2 | G3/4 | 7640148632089 | 713 3304 | ||

TGI 5000E | 5000 | 1300 | 4216 | 4275 | 1010 | G1 1/2 | G3/4 | 7640148632096 | 713 3305 | ||

VN = Nominal volume

*) Special vessel upon request.

**) Tolerance 0 /-100.

***) Max. height when vessel is tilted. Tolerance 0 /-100.

Additional equipment: Pressure limiter Paz PMIN and water level limiter DML Connect.

Primary vessel. Measuring foot for content measurement.

Transfero TGI

Primary vessel. Measuring foot for content measurement.

Type* | VN [l] | D | H | H*** | m [kg] | S | Sw | EAN | Article No | ||

2 bar (PS) | |||||||||||

TGI 1000 | 1000 | 850 | 2199 | 2210 | 280 | G1 1/2 | G3/4 | 7640148631983 | 713 3100 | ||

TGI 1500 | 1500 | 1016 | 2351 | 2381 | 360 | G1 1/2 | G3/4 | 7640148631990 | 713 3101 | ||

TGI 2000 | 2000 | 1016 | 2848 | 2876 | 640 | G1 1/2 | G3/4 | 7640148632003 | 713 3106 | ||

TGI 3000 | 3000 | 1300 | 2951 | 3016 | 800 | G1 1/2 | G3/4 | 7640148632010 | 713 3103 | ||

TGI 4000 | 4000 | 1300 | 3592 | 3633 | 910 | G1 1/2 | G3/4 | 7640148632027 | 713 3104 | ||

TGI 5000 | 5000 | 1300 | 4216 | 4275 | 1010 | G1 1/2 | G3/4 | 7640148632034 | 713 3105 | ||

VN = Nominal volume

*) Special vessel upon request.

**) Tolerance 0 /-100.

***) Max. height when vessel is tilted. Tolerance 0 /-100.

Additional equipment: Pressure limiter Paz PMIN and water level limiter DML Connect.

Hydraulic unit for water make-up operation with Compresso Connect. Water make-up without pumps. 1 solenoid valve, 1 electronic water meter, connection for Pleno P BA4 R.Connection in (Swm): G3/4.Connection out (Sout): G1/2.

Pleno PX

Hydraulic unit for water make-up operation with Compresso Connect. Water make-up without pumps. 1 solenoid valve, 1 electronic water meter, connection for Pleno P BA4 R.

Connection in (Swm): G3/4.

Connection out (Sout): G1/2.

Type | PS [bar] | B | H | T | m [kg] | Pel [kW] | Kvs | EAN | Article No |

PX | 10 | 198 | 356 | 150 | 1,5 | 0,02 | 1,4 | 7640161641792 | 301060-10011 |

T = Depth of the device

Pel = Electric load

Water make-up unit Pleno PX - 25 with 1" connection on request.

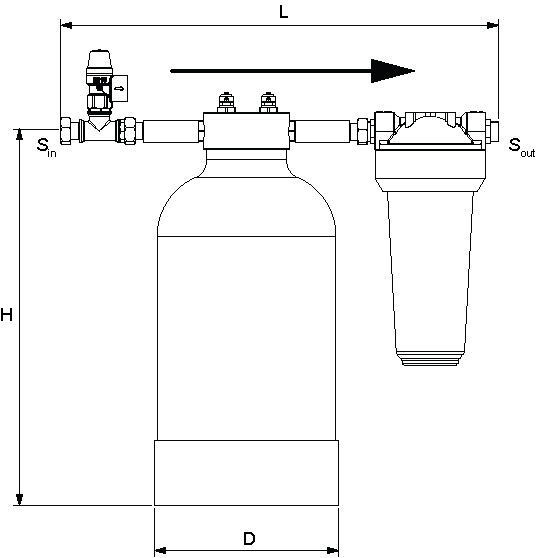

Softening unit

3/4" swivelling nut, 3/4" external thread suitable for flat gasket.

Nominal pressure: PS 8

Max. working temperature: 45°C

Min. working temperature: > 4°C

Type | Capacity l x °dH | Sin | Sout | D | H | L | m [kg] | EAN | Article No |

Refill 16000 | 16000 | G3/4 | G3/4 | 195 | 383 | 455 | 9,1 | 7640161630475 | 813 3210 |

Refill 36000 | 36000 | G3/4 | G3/4 | 220 | 466 | 455 | 13 | 7640161630482 | 813 3220 |

Refill 48000 | 48000 | G3/4 | G3/4 | 270 | 458 | 455 | 16,2 | 7640161630499 | 813 3230 |

→ = Flow direction

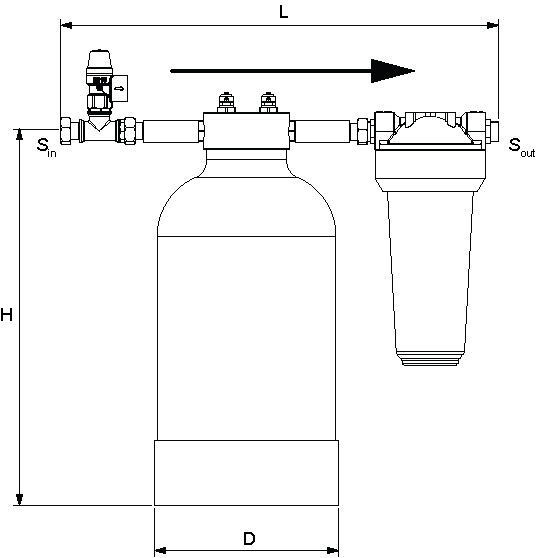

Demineralisation unit

3/4" swivelling nut, 3/4" external thread suitable for flat gasket.

Nominal pressure: PS 8

Max. working temperature: 45°C

Min. working temperature: > 4°C

Type | Capacity l x °dH | Sin | Sout | D | H | L | m [kg] | EAN | Article No |

Refill Demin 13500 | 13500 | G3/4 | G3/4 | 220 | 466 | 455 | 13 | 7640161630505 | 813 3260 |

Refill Demin 18000 | 18000 | G3/4 | G3/4 | 270 | 458 | 455 | 16,2 | 7640161630512 | 813 3270 |

→ = Flow direction

Hydraulic unit for water make-up operation with Vento/Transfero Connect, Pleno PX/PIX, Simply Compresso C 2.1-80 SWM, and in combination with Pleno Refill modules. Features a shut off valve, check valve, filter and a type BA backflow preventer (protection class 4) according to EN 1717.Connection (Swm): G1/2

Pleno P BA4 R

Hydraulic unit for water make-up operation with Vento/Transfero Connect, Pleno PX/PIX, Simply Compresso C 2.1-80 SWM, and in combination with Pleno Refill modules. Features a shut off valve, check valve, filter and a type BA backflow preventer (protection class 4) according to EN 1717.

Connection (Swm): G1/2

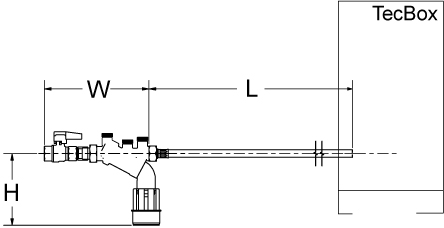

Type | PS [bar] | B | L | H | m [kg] | qwm [l/h] | EAN | Article No |

BA4 R | 10 | 210 | 1300 | 135 | 1,1 | 350* 250** 50*** q(pw-pout) **** | 7640161630147 | 813 3310 |

qwm = make-up water flow

* maximum average value for make-up water degassing with Vento V/VI and Transfero TV/TVI

** maximum average value for make-up water degassing with Vento Compact

*** when using flow limiter for operation with low flow water treatment cartridges

**** for combination with Pleno PX/PIX see q(pw-pout) diagram in Pleno Connect datasheet

T = Depth of the device

Minimum pressure switch. For retrofitting to Transfero TI.Fitting on site into TecBox and connection to control module.TÜV-tested in accordance with VdTÜV Druck 100/1 for specialised equipment and according to PED 2014/68/EU.

Paz PMIN

Minimum pressure switch. For retrofitting to Transfero TI.

Fitting on site into TecBox and connection to control module.

TÜV-tested in accordance with VdTÜV Druck 100/1 for specialised equipment and according to PED 2014/68/EU.

Type | VN [l] | B | H | T | m [kg] | S | dpu [bar] | EAN | Article No |

PMIN 0-6 | 16 | 82 | 180 | 40 | 0,5 | G1/2 | 0-6 | 7640148638821 | 825 1521 |

PMIN 6-16 | 30 | 82 | 194 | 30 | 0,5 | G1/2 | 6-16 | 7640148638845 | 825 1523 |

T = Depth of the device

Minimum pressure switch. Factory fitted to Transfero TI.Pre connected to control module.TÜV-tested in accordance with VdTÜV Druck 100/1 for specialised equipment and according to PED 2014/68/EU.

Paz PMIN TI

Minimum pressure switch. Factory fitted to Transfero TI.

Pre connected to control module.

TÜV-tested in accordance with VdTÜV Druck 100/1 for specialised equipment and according to PED 2014/68/EU.

Type | VN [l] | B | H | T | m [kg] | S | dpu [bar] | EAN | Article No |

PMIN 0-6 TI | 16 | 82 | 180 | 40 | 0,5 | G1/2 | 0-6 | 7640148638814 | 825 1520 |

PMIN 6-16 TI | 30 | 82 | 194 | 30 | 0,5 | G1/2 | 6-16 | 7640148638838 | 825 1522 |

PMIN 0-25 TI | 30 | 133 | 208 | 61 | 0,5 | G1/2 | 0-25 | 7640148638852 | 825 1524 |

T = Depth of the device